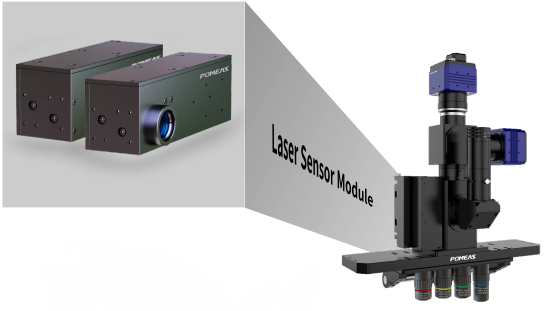

In the field of precision manufacturing, medical research and development and industrial automation, the accuracy and speed of laser focusing is becoming a key indicator of product quality. Traditional sensors are often caught in the dilemma of “not being able to see and catch up” when facing dynamic targets, complex surfaces or extreme environments. POMEAS laser image sensors are redefining the boundaries of precision in industrial vision with their co-axial focusing technology, μm-level accuracy and 6.5kHz response speed. Is your production line ready for this technological innovation?

I. Six dimensions break through the limits of the industry

1. The Co-Axial Focus Revolution: Say Goodbye to Occlusion and Shift

While conventional laser sensors often suffer from focus blockage or shift due to the separation of the optical paths, POMEAS utilizes a co-axial optical design that completely overlaps the optical paths of the transmitting and receiving lasers. This innovation solves the problem of dynamic target tracking and enables “zero-error” focusing, even in the face of specular reflections or transparent materials.

2. 6.5kHz Response Speed: Dynamic Capture Beyond Human Eye Perception

In high-speed scenes such as laser cutting and 3D scanning, the POMEAS sensor realizes real-time tracking with an internal refresh rate of 10kHz and an output rate of 6.5kHz. This means that 6,500 focus adjustments can be made per second, allowing even objects that are moving several meters per second to be “locked on” with pinpoint accuracy.

3. Intelligent surface adaptation: full compatibility from mirrors to fabrics

Through the automatic gain adjustment algorithm, the sensor can adapt itself to the surface reflectivity change under 2X-100X objective lens. Whether it is highly reflective metal, rough fabric or low-contrast carbon fiber, the optimal parameters can be matched automatically, completely freeing up manual debugging costs.

4. Modular Integration: Plug and Play Productivity Tools

Provides dual analog/digital outputs, compatible with PLCs, motion controllers and third-party stepper/piezo Z-axis systems. POMEAS controllers provide closed-loop sensor-actuator control without the need to modify existing equipment.

5. Industrial-grade reliability: 5°C to 50°C without fear of challenge

Full metal body with IP65 protection grade ensures stable operation of the sensor in harsh environments such as oil, vibration and electromagnetic interference.

6. Microscopic Scaling: Enabling Research and Medical Scenarios

Supports direct integration into existing microscope systems, providing cross-scale solutions from cell observation to semiconductor inspection. Paired with POMEAS algorithm libraries, it enables submicron 3D shape reconstruction.

II. Application Scenarios

1. Precision Machining: The “Quality Gatekeeper” for Laser Welding/Cutting

In new energy vehicle battery module welding, the sensor compensates thermal deformation of the weld seam in real time and improves the consistency of the weld joint to 99.9%; in 5G filter cutting, the 6.5kHz response speed ensures that the roughness of the cutting surface is ≤0.5μm.

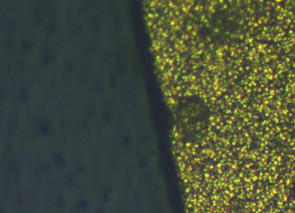

2. Industrial Inspection: The “Fire Eye” of 3D Vision

Provide online inspection solutions for power battery pole piece, chip packaging and other scenarios.

3. Life Sciences: “Intelligent Assistants” for Microscopic Observations

In live cell imaging, the sensor automatically compensates for the out-of-focus caused by cell movement, and the imaging clarity degradation is <5% for 48 consecutive hours, providing reliable data support for drug discovery and development.

III. Why POMEAS?

· Technical certification: CE, ISO and other international certifications, in line with Industry 4.0 standards

· Customized service: provide full-process support from sensor selection, algorithm development to system integration

· Eco-compatible: supports multiple industrial protocols.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com