In the field of industrial inspection, where the pursuit of ultimate precision and efficiency often strains a single measurement method, the MetX Multi-Sensor Measurement System was born, perfectly integrating 2D vision measurement and 3D sensing technology to provide you with an unprecedentedly comprehensive, precise, and efficient measurement experience. Its core strengths are reflected in the synergistic innovation of four key modules:

I. Flexible Motion Module

1. Platform Configuration: Provide cantilever type (space-saving, flexible operation) or gantry type (high rigidity, large stroke, stable and reliable) two classic structures.

2. Advantage: Adapt to the measurement needs of different sizes and weights of workpieces, ensure the stable performance of the system in high-speed, high-precision movement, laying a solid foundation for accurate measurement.

II. Superior Optics Module

1.1 Optical Module - 6.5X high-magnification continuous zoom lens: Seamless switching from macroscopic to microscopic vision without changing lenses, greatly improving inspection efficiency.

1.2 Optical Module--Professional Light Source Combination: Provide various lighting solutions (e.g. ring light, coaxial light, backlight, etc.), which can easily cope with complex surface features (highly reflective, dark color, texture, etc.), and present the best imaging effect.

1.3 Optical Module - 10 million high-resolution color industrial camera: Capture clear and detailed 2D images to ensure the accuracy of 2D measurement results such as dimensions, appearance, defects, and so on.

2. Advantage: Provide top 2D visual imaging capability, offering reliable guarantee for dimensional measurement, appearance inspection, positioning guidance, etc.

III. Precision 3D Sensor Module

1. Sensing module: Integration of advanced point spectrum confocal sensor and contour scanning line laser or point laser sensor.

2. Advantage: breaking through the 2D limitations, realizing non-contact, high-precision measurement of height, segment difference, flatness, contour and other three-dimensional morphological features. Especially good at measuring objects that are difficult to handle by traditional methods, such as transparent, mirrored surfaces and multi-layer materials.

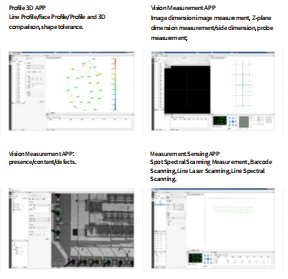

IV. Measurement Software: MetX Multi-Sensor Measurement Software

1. Powerful compatibility: Seamlessly support all 2D cameras and 3D sensors integrated in the system, realizing true multi-sensor cooperative work and data fusion.

2. Comprehensive measurement: One platform can complete the measurement of size (length, width and height), shape, position, contour, segment difference, flatness and other 2D & 3D parameters.

3. Simple operation: Intuitive and friendly user interface, flow wizard design, significantly reduce the threshold of operation and learning costs.

4. Intelligent algorithms: equipped with powerful surface processing algorithms to effectively overcome shadows, reflections, noise and other interference, to ensure the stability and repeatability of the measurement results.

5. Efficient Batch Processing: Unique rapid measurement tools for multiple identical products, can be copied with one key measurement program, greatly enhancing the efficiency of batch product inspection.

6. Rich tools: provide a diverse library of measurement tools (such as points, lines, circles, rectangles, distances, angles, contour comparison, flatness analysis, etc.), a flexible response to a variety of complex measurement needs.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com