LPS Line Laser Profile Sensor,High-speed capture of 3D contours and 2D dimensions

On high-speed assembly lines, where accurate measurement of product dimensions and contours has been a bottleneck in efficiency, the LPS series of line laser contour sensors, with an ultra-high-speed full-frame frame rate of 12,000Hz, realizes simultaneous on-line measurement of product 3D shape and flat dimensions (length/width/height).

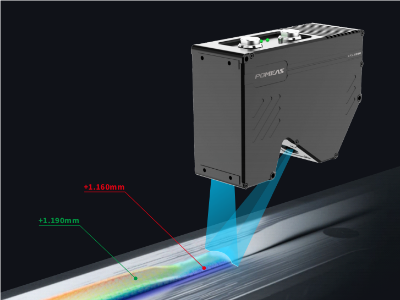

Line laser profile sensor measurement principle:

The laser beam is diffused into a stable linear light source through a high-precision cylindrical objective lens and projected onto the surface of the object to form a diffuse reflection; the reflected light is imaged by the optical system in the CMOS sensor, and the displacement and contour shape of the target are calculated in real time by analyzing the positional offset and deformation data of the laser line to ensure that the depth information of the complex surfaces is captured without loss.

Solving multiple pain points in industrial inspection

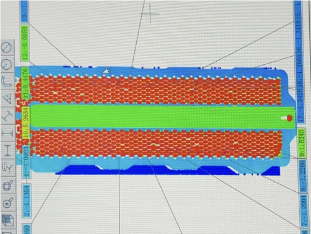

(1)2D dimensional measurement: automatic output of key dimensions such as length, width, height, etc.

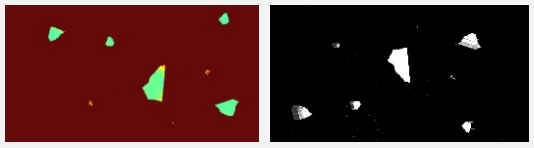

(2)Detection of impurities: identification of foreign matter adhering to surfaces

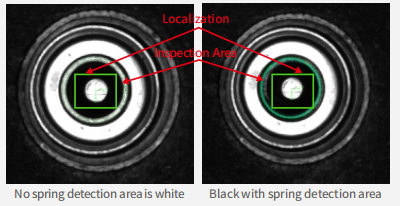

(3)Detection of presence/absence; accurate determination of missing/misplaced parts

(4)Defect detection: captures micron-sized defects such as scratches, pits, burrs, etc.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION