Telecentric Measurement System Case: Inspection of Cylindrical Dimensions

In the field of industrial production and quality inspection, the dimensional inspection of cylindrical parts is an extremely important task, and its accuracy directly affects the performance and quality of products. Traditional measurement methods are often cumbersome, inefficient, and prone to human interference, it is difficult to meet the modern manufacturing industry on the demand for high-precision, high-efficiency testing. The emergence of Telecentric Measurement System brings a revolutionary solution for cylindrical size inspection.

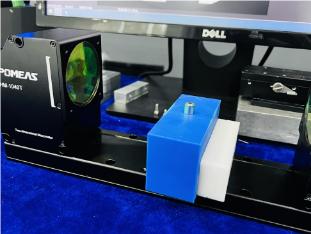

The inspection process of the Telecentric Measurement System is very easy. When it is necessary to check the dimensions of a cylinder, the operator only needs to place the cylindrical product smoothly on the platform of the measuring instrument. The high-resolution image acquisition system inside the instrument will be activated quickly, and the cylindrical product will be photographed from different angles by several sets of high-definition cameras. These cameras are equipped with advanced optical lenses that can accurately capture every detail of the cylinder, ensuring the clarity and accuracy of the image.

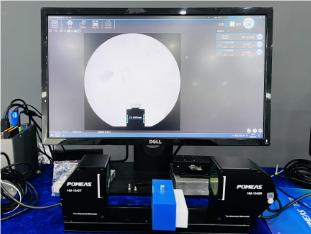

The image data is then quickly transferred to the high-performance image processing and analysis system built into the measuring instrument. Supported by powerful algorithms, the system processes the acquired images in depth, quickly separates the contours of the cylindrical product from the background and presents them in a clear, intuitive projection on the display. Both the outer contour of the cylinder and the inner subtle structure can be completely presented on the display.

More critically, the Telecentric Measurement System is equipped with a powerful dimension calculation function. It can automatically analyze and calculate the projected cylindrical profile based on preset measurement standards and algorithms, so as to quickly and accurately obtain key dimensional information of the cylinder, including height and diameter. During the calculation process, the measuring instrument will comprehensively analyze and process the measurement data from multiple angles, effectively eliminating the measurement errors caused by factors such as non-standard placement of the cylinder and deviation of the shooting angle, ensuring the high accuracy and reliability of the measurement results.

The measurement process is fully automated, from image acquisition to size calculation in one go, which significantly shortens the inspection time, significantly improves the inspection efficiency, and meets the needs of rapid inspection in large-scale production; the digitized measurement results are easy to store, manage and analyze, which is convenient for enterprises to carry out quality traceability and optimization of the production process.

Telecentric Measurement System, with its simple and convenient operation process, accurate and efficient measurement performance, provides a brand new solution for cylindrical size inspection, and plays an important role in the quality inspection link of modern manufacturing industry.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com