Are you curious about how small parts are accurately inspected in factories? Today, let's take a look at a few vivid examples of how online image measuring instruments can help you find the “eyes of gold”!

Case 1: Screw Size Measurement

In automobile manufacturing, a deviation of 0.01 millimeter in the thread diameter of a screw may lead to engine oil leakage. The online image measuring instrument shoots the surface of the screw with a high-definition camera, automatically compares the design drawings using image algorithms, and completes the detection of 20 parameters such as thread pitch and head diameter in 1 second with micron-level accuracy, so that defects have no place to hide.

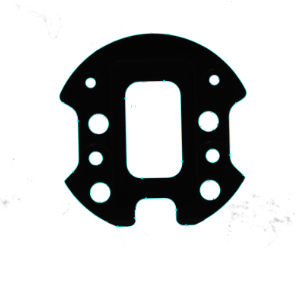

Case 2: Profile Inspection of Metal Parts

Spacecraft parts have nearly demanding contour requirements. Traditional inspection requires manual comparison of drawings, while the image measuring instrument can capture the three-dimensional contour of metal parts in real time, generating point cloud data superimposed on the standard model for comparison. Even a 0.02-millimeter edge burr can be marked with red highlights, just like doing a “CT scan” of the part.

Case 3: Centricity Detection

The roundness of bearing balls directly affects the operating life of machinery. The measuring instrument uses edge extraction technology to lock the arc and calculate the offset between the actual center and the theoretical center. Even in the face of blurred images on high-speed production lines, sub-pixel technology restores the true contours and ensures that every part is “centered”.

Case 4: Wire Diameter Measurement

Deviations in wire diameter of wires and cables may cause safety hazards. The measuring instrument utilizes a binocular vision system to capture the wire cross-section from different angles, combined with laser ranging to correct for deformation errors. Even in the face of enameled wires with a diameter of only 0.5 mm, fluctuations of 0.005 mm can be accurately measured.

See here, do you have a new perception of industrial quality inspection “black technology”? What kind of precision testing equipment have you seen that makes you marvel? Welcome to leave a message to share your insights, or put forward the industrial measurement problems you want to understand, the next issue of science for you to reveal the secret!

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION