Have you ever had the headache of repeatedly measuring part dimensions? Or have you ever had to rework a product due to manual errors? In industrial manufacturing, quality inspection and other scenarios, accurate and efficient dimensional measurement is the key to quality control - have you encountered similar efficiency bottlenecks? Welcome to share your measurement problems in the background!

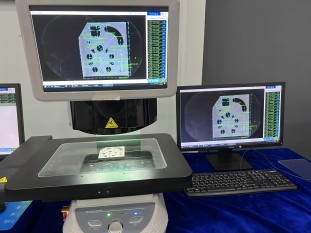

In modern manufacturing industry, accurate and efficient dimensional measurement is the key link to ensure product quality and productivity. As an advanced measuring tool, one-button dimensional measuring instrument has been widely used in many fields by virtue of its intelligent and automated features. For example:

A:Manufacture of Automotive Parts and Components

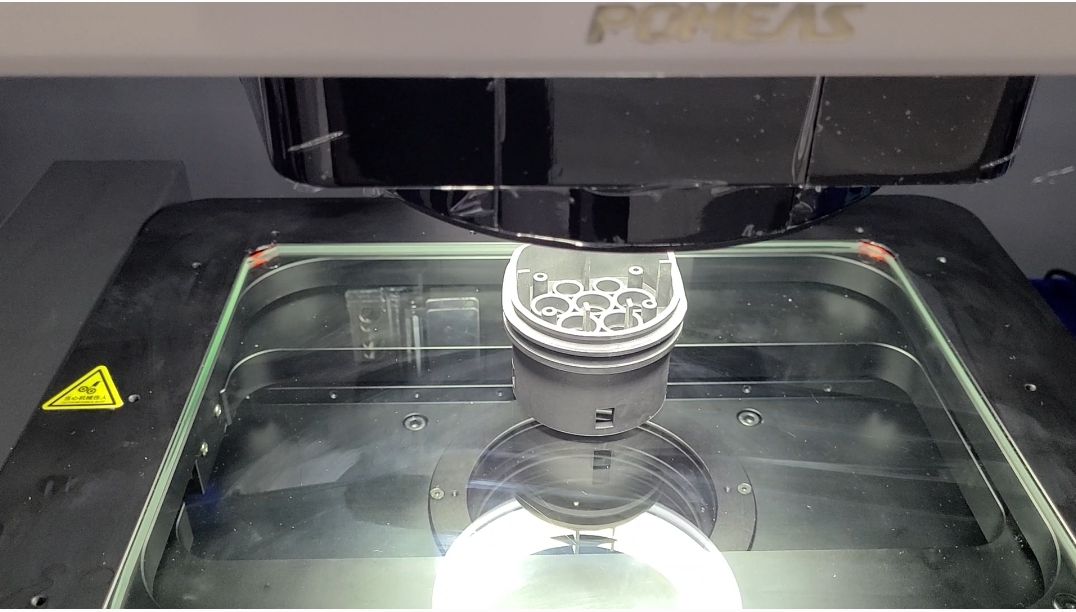

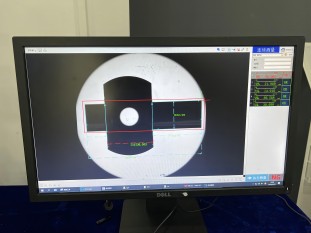

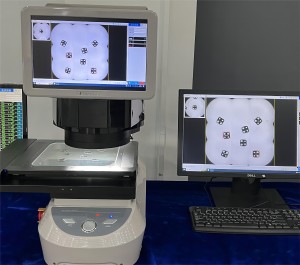

In the automotive manufacturing industry, the dimensional accuracy of components is directly related to the performance and safety of the entire vehicle. The one-button dimensional measuring instrument detects the dimensions of key components such as engine blocks and gearbox housings, and through non-contact scanning technology, it is able to complete the three-dimensional dimensional measurement of complex shaped components in a short period of time, and the measurement accuracy is as high as the micron level. This not only greatly improves the measurement efficiency, but also effectively reduces human measurement errors and ensures the consistency and reliability of the parts.

B:Aerospace

In the aerospace field, the dimensional accuracy of components is required to be extremely high. One-button dimensional gauges are widely used in the measurement of precision parts such as aircraft engine blades and fuselage structural parts. Through high-precision scanning and data analysis, the gauges are able to accurately identify minute dimensional deviations of components, providing strong support for design optimization and production improvement.

C:Manufacture of Consumer Electronics

In the field of consumer electronics manufacturing, the one-touch size measuring instrument provides accurate measurements of key components such as cell phone shells and screens. Through the measurement data, the enterprise can discover the size deviation in the production process in time, adjust the production process in time, and ensure that each cell phone meets the design requirements. The overall quality of the product is improved.

D:Mold Design and Manufacturing

In the field of mold design and manufacturing, One Touch Dimension Measuring Instrument measures the mold accurately and obtains the three-dimensional dimension data of the mold. These data provide an important basis for mold design optimization and production improvement. At the same time, through the comparison and analysis of the measurement data, the enterprise is also able to find out the problems of mold wear and deformation in time, and take timely measures to repair and replace them, which ensures the precision and life of the mold.

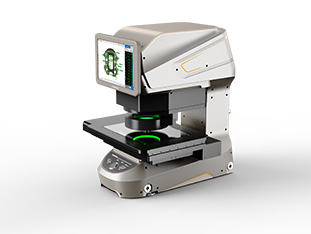

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com