Learn about the advantages of motorized zoom autofocus microscopes

Have you ever experienced such crashing moments when adjusting a microscope in the lab or on the production line: the manual knob stutters and causes blurring of the sample, the target disappears after repeated magnification adjustments, or the uneven illumination makes defects “invisible”? These pain points are being completely changed by the new generation of motorized zoom autofocus microscopes.

1. Switching magnification is a breeze

0.7X 4.5X

The manual zoom mechanism of traditional microscopes is often jammed due to mechanical wear and tear, while the motorized zoom lens is driven by a stepper motor to achieve 0.7X-4.5X continuous zoom with a switching speed of up to 2 seconds/stage. What's more, its built-in closed-loop control system can complete automatic focus compensation at the moment of zoom, ensuring that the samples are always as clear as ever when scanning from low magnification to high magnification observation.

2. Quadrant light source to create a “shadowless light” effect

The unique quadrant LED ring light design can independently adjust the brightness and angle of the four quadrants. When detecting metal reflective parts, 15° oblique light is formed through program control, effectively suppressing specular reflection; when observing plastic parts, the light is switched to 30° diffuse light, making scratches and bubbles invisible. This intelligent lighting system reduces the detection blind spot by 85% and the defect detection rate exceeds 99.9%.

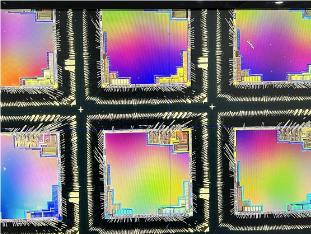

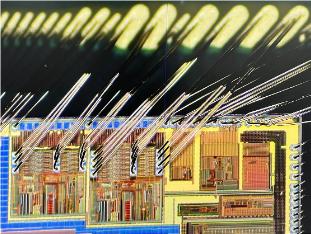

3. Image Stitching Unlocks “Panoramic Vision”

Equipped with AI-driven image stitching algorithms, the device can complete the automatic acquisition and fusion of 9×9 images in 30 seconds, generating a panoramic image with a resolution of 120 million pixels. In the wafer inspection scenario, engineers can view the entire chip package area at once, reducing the leakage rate from 5% to 0.3% of the traditional solution.

4. Measurement report generation at the touch of a button

The integrated non-contact ranging module supports the measurement of 12 parameters, such as length, angle, area, etc., with an accuracy of ±1 μm. After the inspection is completed, the system automatically generates a PDF report labeled with the location of defects, dimensional data, and can be docked to the MES system to achieve quality traceability. After the application of an auto parts manufacturer, the processing time of quality inspection documents was shortened by 75%.

Is your industry facing similar inspection challenges? Perhaps it's time to upgrade your microscope from an observation tool to an intelligent inspection platform - share your inspection pain points or leave a comment to get product information about motorized zoom autofocus microscopes!

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com