Beginner's Guide | Differences between telecentric and industrial lenses

In the field of machine vision, the lens is the core component that connects the optical system and digital image. Telecentric lens and industrial lens as the two mainstream types, although often referred to collectively as “industrial lens”, but the two in the optical principle, structural design and application of the scene there are essential differences. Now from the principle, appearance, application of the three aspects of the comparison, to help novices quickly establish a systematic knowledge.

A、Principles of Optics

1.1 Telecentric lens - precision design to eliminate perspective errors

The core advantage of the telecentric lens is its unique image-square telecentric optical path structure:

① aperture diaphragm position: the aperture diaphragm is precisely placed at the focal plane of the object side to ensure that the main light from the object side enters the lens in the form of a parallel optical axis.

② imaging characteristics: the main light rays from the image side converge at infinity, making the image size of the object to be measured independent of the object distance. Even if the object moves within the depth of field, its imaging size remains constant.

③ technical value: completely solve the problem of perspective aberration caused by the change of object distance of traditional lens, and provide theoretical guarantee for high-precision measurement.

1.2 Industrial lenses - co-optimization of multiple lens groups

Industrial lenses adopt modular lens group design:

① structural composition: composed of multiple lens groups with specific functions (such as focusing group, correction group), balancing the aberration through precise arrangement.

② adaptability advantage: by adjusting the lens spacing or replacing the lens group, it can be adapted to different working distances (WD) and field of view requirements, and maintain imaging clarity in dynamic scenes.

③ core indicators: comprehensive evaluation of performance with parameters such as resolution, aberration rate, aperture value (F-number), etc., emphasizing compatibility with complex environments.

B、Appearance

2.1 Telecentric lenses - magnification determines volume

① size law: magnification and volume are inversely related. Low magnification (e.g. 0.1×) lenses need to accommodate a large image plane sensor, the physical size is larger; high magnification (e.g. 2×) lenses are more compact.

② design features: usually equipped with precision focusing mechanism, some models integrated coaxial light source interface, in order to adapt to the needs of high-precision detection.

2.2 Industrial lens - prioritizing space efficiency

① compact design: through the optimization of lens arrangement and housing materials, to achieve lightweight and miniaturization, reducing the space occupied by the inspection equipment.

② interface standardization: provide C/CS/M42 and other interfaces, compatible with mainstream industrial cameras, easy to quickly deploy.

C、Application Scenarios

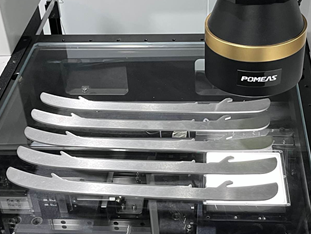

3.1 Telecentric lenses - an exclusive tool for precision measurements

① dimension measurement: in 3C electronics, semiconductor and other industries, measuring component aperture, line width and other parameters, the error can be controlled at the micron level.

② defect detection: identify metal parts burrs, glass scratches and other small defects, to avoid leakage caused by perspective errors.

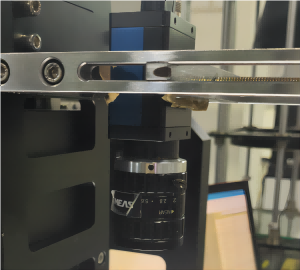

3.2 Industrial lenses - versatile for visual positioning

① robot guidance: provide real-time position feedback for the robotic arm, with an accuracy of 0.1mm.

② barcode recognition: fast reading of dynamic barcodes in logistics sorting, need to take into account the depth of field and reading speed.

Telecentric lenses and industrial lenses are essentially a trade-off between the pursuit of precision and the need for versatility. In the field of precision manufacturing, quality inspection, telecentric lenses with “zero error” imaging capability has become a necessity; while in logistics, security and other scenes, the flexibility and cost advantages of industrial lenses are more favorable.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com