In the industrial vision system, industrial zoom lens is widely used in precision inspection, quality monitoring and other scenarios due to its flexible magnification adjustment ability and high precision imaging characteristics. However, in the face of complex lens models and accessories, novice users are often confused in the selection process. In this article, we will systematically sort out the selection steps of industrial zoom lens to help users from interface adaptation, magnification matching to the light source configuration, and quickly master the core matching logic.

I. Confirmation of camera interface and adapter requirements

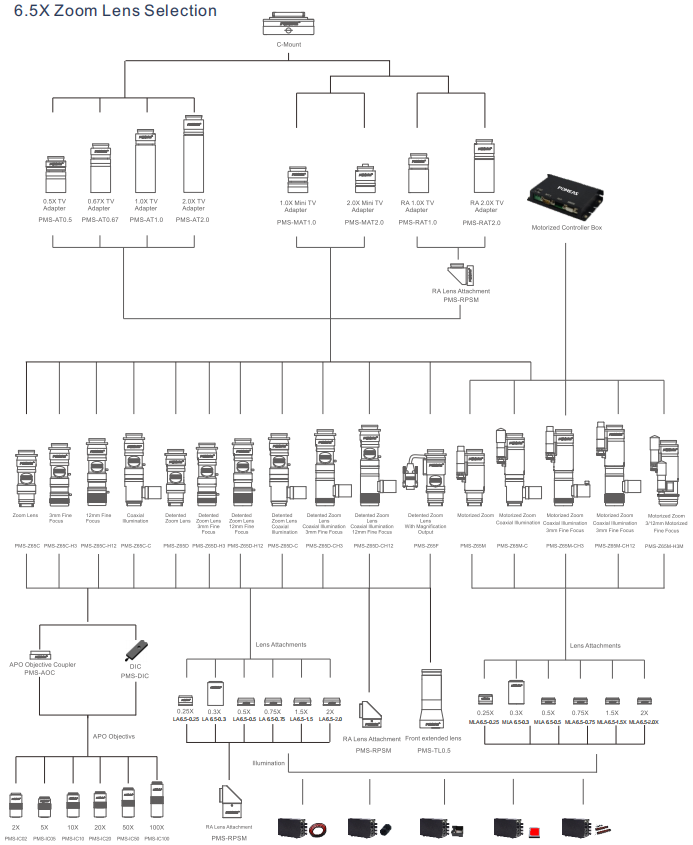

Industrial zoom lens selection needs to be based on the camera interface to ensure mechanical and electrical compatibility, industrial zoom lens conventional interface is mostly C interface (1 inch thread, flange distance 17.526mm), C interface is commonly used in small and medium-sized industrial cameras, wide compatibility, suitable for most of the basic application scenarios; if the lens interface does not match the camera interface, you need to use the adapter interface (eg: F-to-C adapter ring). Confirmation of the camera interface and adapter requirements

Points to consider:Check the camera manual to confirm the type of interface, and prioritize the model that matches the native interface of the lens to avoid increasing aberration or decreasing the structural stability due to the transfer interface; if you need to transfer the interface, prioritize the brand's official accessories to ensure the concentricity and precision.

II. Match the TV tube according to the magnification requirements (in special cases, also add the steering gear) with the key points

The magnification range of the industrial zoom lens (hereinafter take 0.7X-4.5X as an example) needs to be adjusted the working distance and field of view by the TV lens barrel (extension tube).

1. Calculation of magnification and lens tube length: the longer the lens tube, the greater the working distance, but the field of view will be reduced. Calculate the required magnification and barrel length according to the target size and detection accuracy. (Example: If the detection of 30mm diameter workpiece, the camera target surface is 1/2 inch (8mm diagonal), the lens magnification to meet: field of view ≤ target size / magnification)

2. 90 ° steering application scenarios: when the detection of space constraints, 90 ° steering can be used to change the direction of the optical path, but need to (Note: steering will introduce additional aberration, need to choose a low-distortion models; need to recalculate the working distance and magnification to avoid image distortion.) Draw a schematic diagram of the inspection scene, mark the size of the target, space constraints and camera position, and simulate the imaging effect under different lens barrel combinations through the lens selection software; prioritize the lens barrels that support the magnification scale markings for quick adjustment.

Points to consider:Draw a schematic diagram of the inspection scene, mark the size of the target, space limitations and camera position, and simulate the imaging effect under different combinations of lens barrels through the lens selection software; prioritize the selection of lens barrels that support the magnification scale marking to facilitate rapid adjustment.

III. Auxiliary Objective Lens Matching: Manual vs. Motorized Zoom Lens

Auxiliary objective lenses are used to extend the lens magnification range or correct aberration, and need to be selected according to the lens type:

1. Manual zoom lens: the image quality can be improved by adding APO (compound achromatic aberration) interface with APO objective lens, especially suitable for high-precision measurement scenarios.

Points to consider:If the base magnification of the lens is 0.7X-4.5X, it can be matched with 0.5X-2X APO objective lens to realize wider magnification coverage (0.35X-9X). APO objective lens should be matched with the lens magnification range to avoid blurring of the edges due to the conflict of the magnification.

2. Motorized zoom lens: usually built-in high-precision stepping motor, supports remote control of magnification switching. (Note: Motorized lenses may not be able to mount APO objectives directly, so you need to choose a compatible model or realize it through a customized interface).

Points to consider:Define the requirements of the inspection task in terms of magnification switching speed, accuracy and image quality, and choose manual or motorized lenses in conjunction with your budget.

IV. Optimization of light source selection and matching

Light source is the core element of machine vision system, which directly affects the imaging quality.

1. point light source: suitable for high-precision positioning and measurement, such as chip pin detection, precision parts size measurement.

2. ring light source: provides uniform illumination and reduces shadows, suitable for surface defect detection and character recognition.

3. surface light source: suitable for large area uniform illumination, such as PCB board inspection, large workpiece surface inspection. According to the target material (metal, plastic, glass, etc.) and surface characteristics (reflective, transmissive) to choose the type of light source; adjust the angle and intensity of the light source through experiments, for example: detection of reflective surfaces, the use of low angle ring light to reduce glare. When detecting transparent materials, backlighting is used to highlight the contours.

Points to consider:According to the target material (metal, plastic, glass, etc.) and surface characteristics (reflective, transmissive) to choose the type of light source; through the experiment to adjust the angle and intensity of the light source, for example: the detection of reflective surfaces, the use of low angle ring light to reduce glare. When detecting transparent materials, backlighting is used to highlight the contours.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com