Beginner's Guide | Four Features of Embedded On-Line Measuring Instruments

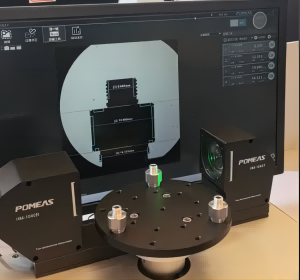

In the field of precision manufacturing, dimensional measurement directly affects product quality and production efficiency. With its revolutionary design, the Embedded In-Line Measuring Instrument is becoming the quality guardian of precision hardware, plastic parts, 3C electronics and other industries. This intelligent device integrates “fast, accurate, simple and smart”, redefining the industrial measurement standard through four core advantages.

A. Extremely Fast Response: Seconds Measurement Revolutionizes Line Efficiency

The embedded measuring instrument has a built-in telecentric optical system that receives only parallel light, making it less susceptible to ambient light and less susceptible to changes in image size when thermal expansion occurs, fully suppressing the effects of temperature changes. Full-size data acquisition can be accomplished in 0.001 seconds by simply placing the workpiece on the measuring platform. More than 10 times the efficiency of traditional measuring equipment, especially for rapid detection of precision parts, single-day detection up to 10,000 pieces level.

B. Micron-Level Precision: Breakthrough Measurement Limits

In the case of product flow can still maintain 0.1μm (0.0001mm) measurement accuracy, for precision manufacturing products to ensure quality and reduce errors, this accuracy is equivalent to 1/800 of the diameter of a human hair, accurate detection of semiconductor lead frame pin spacing, medical minimally invasive instruments, such as the thickness of the tube wall and other ultra-precise dimensions.

C. Intelligent Guidance System: Zero Basis For Quick Mastery

Self-developed measurement software, user-friendly interface, simplified operating steps, with text labeling guidance, reducing training costs, suitable for rapid induction, significantly reducing the technical threshold.

D. The Invisible Guard of The Production Line Space

Designed with embedded architecture, the whole machine size (260×70×30mm) is only equivalent to 1/5 of the traditional equipment, and supports 6 installation modes, such as hanging type and rail type. Through the industrial Internet of Things protocol can be with the robotic arm, realizing 100% online full inspection, successfully solving the industry pain point of sampling omission in the continuous production of automotive parts.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION