In the field of industrial manufacturing, flanges are used as key connecting parts of pipelines, valves, pumps and other equipment, and their dimensional accuracy directly affects the sealing, stability and operational efficiency of the equipment. Traditional measurement methods are limited by equipment precision and operating environment, and it is difficult to meet the demand for high-precision production. The introduction of double magnification + parallel light path technology has brought a revolutionary breakthrough for flange size measurement through the revolutionary design of optical system.

What do flanges need to be measured?

Flange dimensional measurements cover key parameters such as outside diameter, inside diameter, bore diameter, bore distance, thickness and bolt hole center distance.

Does the flange need to be measured for difficulty?

Traditional measuring tools such as vernier calipers and inside micrometers are easy to operate, but are limited by the physical contact deformation and human reading errors of contact measurement. Coordinate Measuring Machine (CMM) has high accuracy but low measurement efficiency, which makes it difficult to adapt to mass production scenarios.

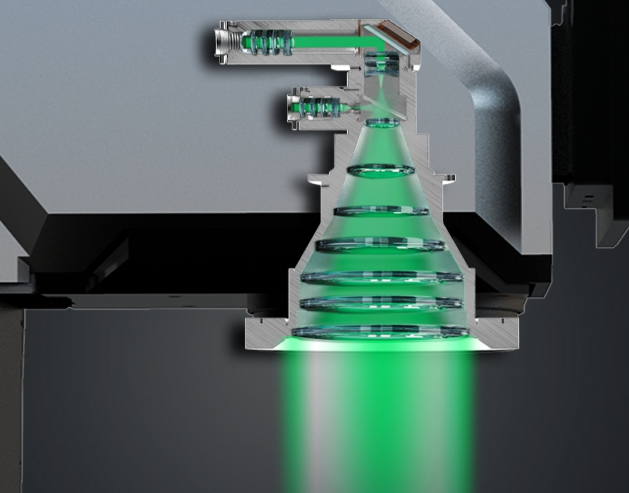

Advantages of double magnification + parallel light path

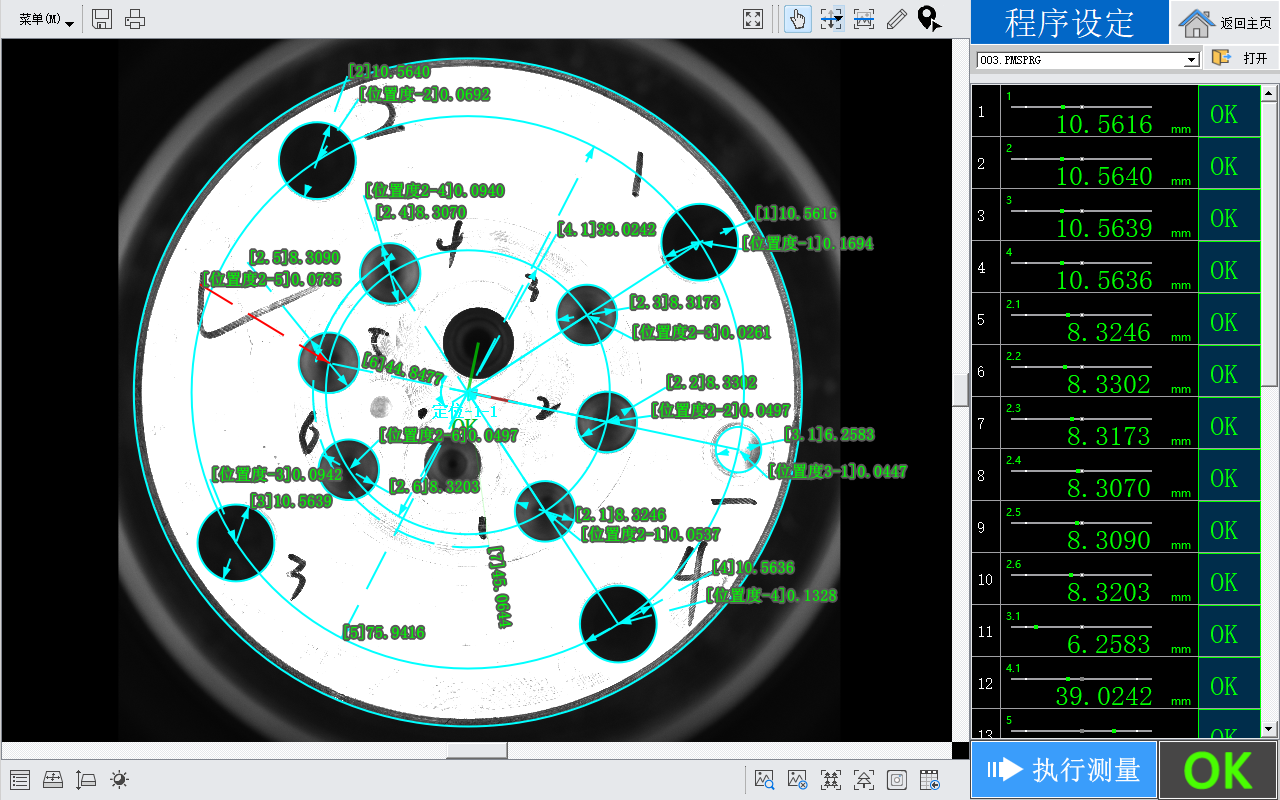

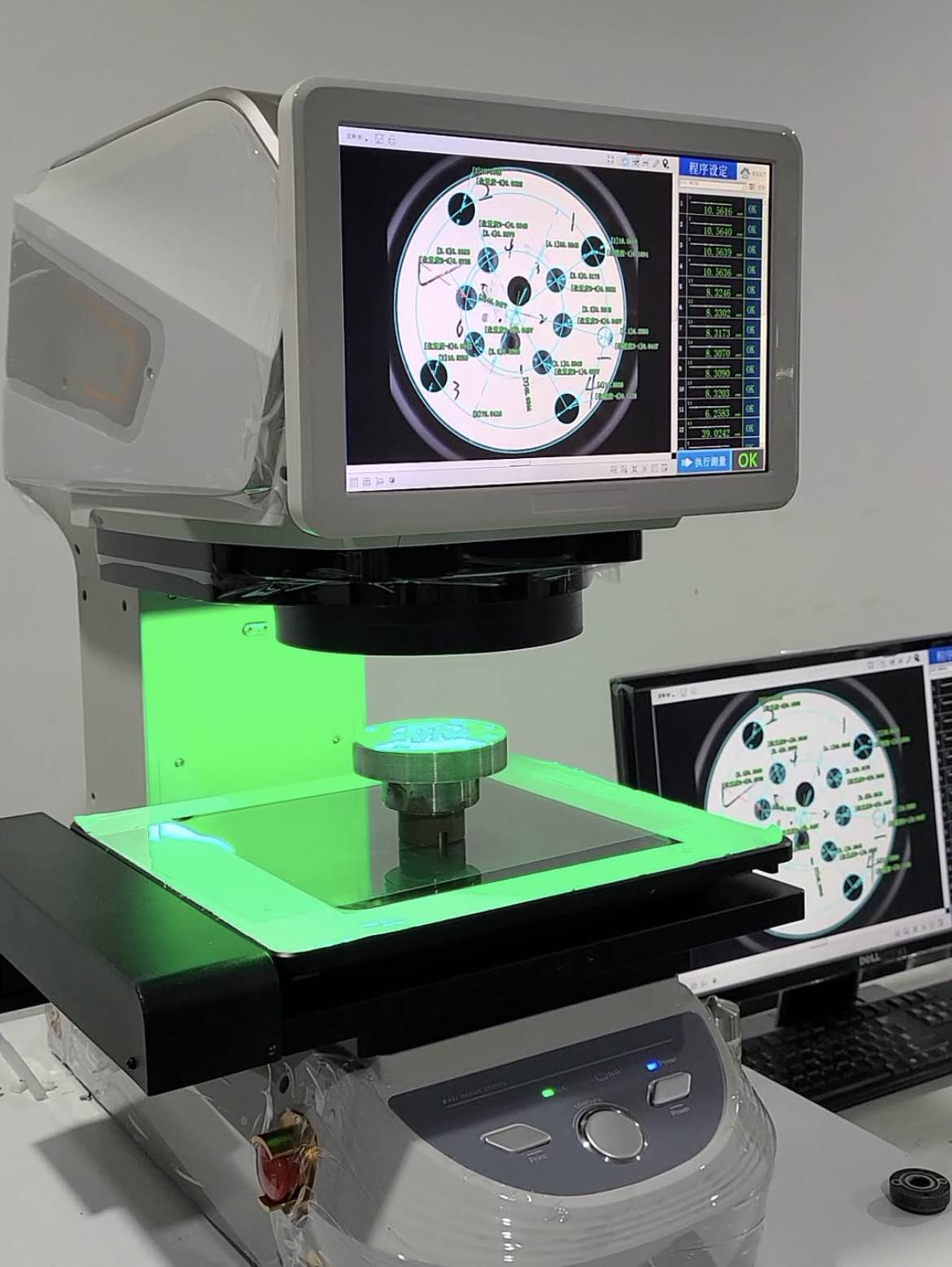

1. Dual-magnification optical system: 0.16X/0.7X high-precision dual-magnification double-side telecentric lenses are used, which take into account the large field of view and high resolution. For example, POMEAS IMAGE 3 image size measuring instrument can complete the flange full-size data acquisition in one time, covering a measuring range of 20mm to 500mm, with a thickness measurement accuracy of ±1μm.

2. Parallel optical path design: The main light rays of the object side and image side are parallel to the optical axis, eliminating the effect of object distance and image distance changes on magnification. This feature makes the measurement results are not affected by the angle of workpiece placement, and the repeatability error is ≤0.5μm.

3. Advantages of dual telecentric optical path: aberration rate <0.01%, much lower than the traditional lens of 0.1%; depth of field range expanded by 3 times, adapted to the complex surface measurement; illumination uniformity increased by 40%, reducing shadow interference.

Application Programs

1. Image Gauge Integration Solution: The POMEAS IMAGE 3 device utilizes a 12 megapixel CCD camera in conjunction with a 100mm green parallel substrate light source to achieve a full size scan of the flange surface.

2.3D contour measuring equipment laser 3D scanner adopts 0.02mm scanning accuracy, combined with double telecentric lens, can reconstruct the flange surface topography.

① Accuracy Improvement: Dual-magnification lens improves the diameter measurement accuracy from ±5μm to ±1μm, and the repeatability of hole distance measurement reaches 0.5μm;

② Efficiency optimization: single-piece flange inspection time is shortened from 15 minutes to 3 minutes, supporting 24-hour continuous operation;

③ Cost reduction: reduce the need for manual re-inspection, saving more than a million dollars in annual quality inspection costs;

④ Application expansion: from traditional machining to high-end manufacturing fields such as aerospace and semiconductor.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com