In the increasingly fierce competition in the manufacturing industry, product quality control has become the key for enterprises to gain a foothold in the market. Small parts as a basic component of many products, its quality directly affects the overall product performance. Desktop flash tester with unique advantages, in the field of small parts testing rapidly popularized for the manufacturing industry to bring innovation in quality control.

Desktop Flash Meter Overview

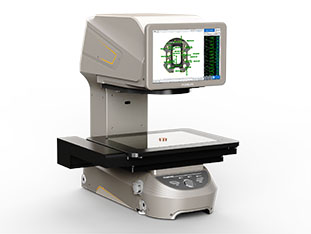

Desktop flash tester is a new type of testing equipment integrating optical imaging, image processing and precision measurement technology. Compared with traditional testing instruments, it is easy to operate, the complexity of the inspection process is simplified, ordinary operators can get started after simple training.

Desktop flash tester detection speed is amazing, can be completed in a very short period of time on small parts of multiple size measurement, greatly improving the detection efficiency. In terms of accuracy, desktop flash tester with advanced optical system and algorithms, to achieve micron-level measurement accuracy, to meet the requirements of various types of high-precision small parts inspection. In addition, the equipment occupies a small space, can be flexibly placed in the production site or laboratory desktop, easy to use.

Application in dimensional inspection of small parts

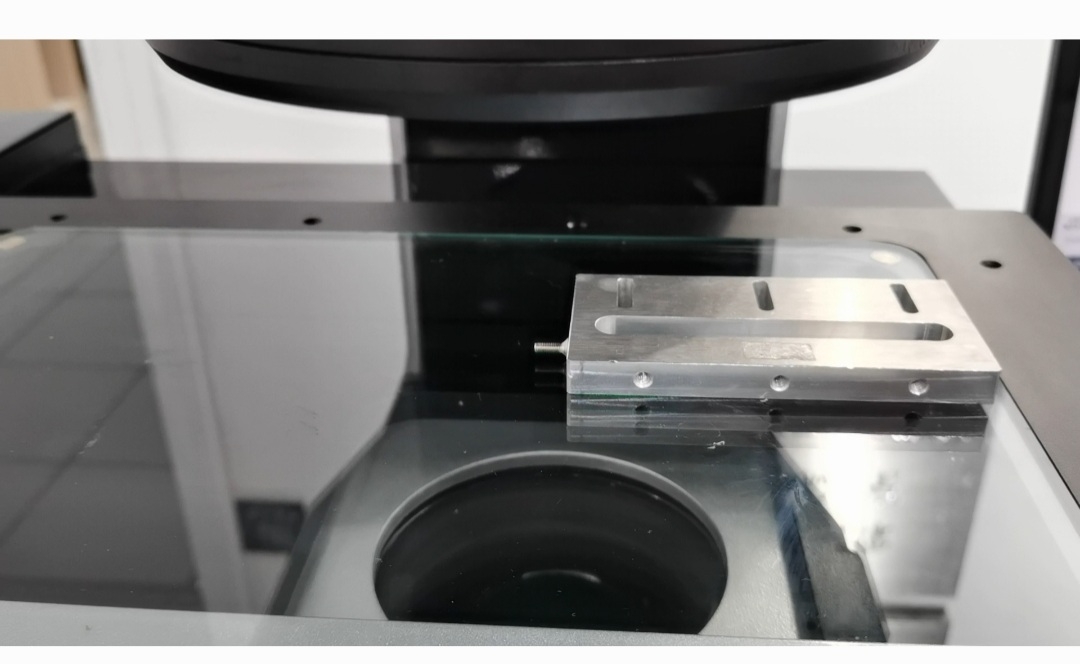

The dimensional accuracy of small parts is a key factor affecting product performance. Take the miniature screws inside a cell phone as an example, its diameter, length, pitch and other dimensional accuracy requirements are extremely high. The desktop flash tester collects images of the parts through a high-definition optical lens, analyzes the images using image processing algorithms, and quickly and accurately measures the dimensional parameters of the screws.

At the same time, the measured data and preset standard values for comparison, automatically determine whether the part size is qualified. For unqualified products, the system can also accurately locate the problem, provide a basis for the improvement of the production process, to avoid product quality problems caused by dimensional deviations.

Application to assembly integrity testing of small parts

Many small parts need to be assembled, and the integrity of the assembly is directly related to the performance and reliability of the product. Taking small motors as an example, the desktop flash tester analyzes the overall image of the motor after assembly and detects whether the internal parts of the motor are missing or misplaced. At the same time, the sealing of the motor shell is detected to ensure that the motor will not have leakage, water ingress and other problems during operation.

With the help of this function, problems in the assembly process can be detected in time, product quality accidents caused by improper assembly can be avoided, and production costs can be reduced.

Desktop flash tester provides a new solution for small parts inspection with its advantages of high efficiency, accuracy and convenience. In the context of the transformation and upgrading of the manufacturing industry, desktop flash tester will play a greater role in promoting the manufacturing industry to high-quality development.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com