Programmatic background

In the field of industrial production and inspection, there is a growing demand for scanning the appearance of product contours and dimensional measurement. For simple measurement requirements, and the size of the product is not larger than 200mm scene, build a set of cost-effective line laser sensor 3D scanning program is very practical value.

Program core components

A、Measurement software MetX

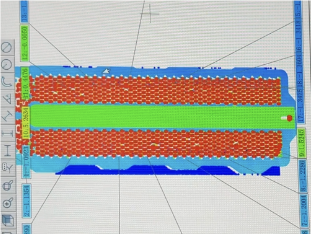

Measurement Soft MetX is the data processing hub of the entire solution. It is feature-rich with powerful point cloud data processing capability, which can de-noise and filter the raw data collected by the sensor to ensure the accuracy of the data. During the measurement process, the software can automatically identify the characteristic points of the measurement target, quickly complete the size calculation, such as length, diameter, angle, etc., and output an intuitive and accurate measurement report for the user. In addition, the software has a simple interface and supports user-defined measurement parameters, which can be easily adapted to different measurement tasks, greatly reducing the threshold of use.

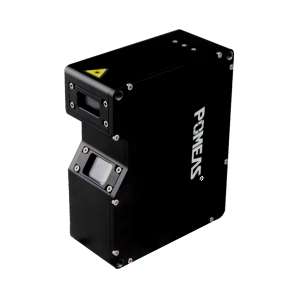

B、3D Contour Scanning Sensor

The 3D contour scanning sensor, as the key equipment for data acquisition, works based on the principle of line laser triangulation. When the line laser emitted by the sensor irradiates the surface of the object to be measured, the reflected light is received by the camera inside the sensor, and by calculating the position change of the laser line on the imaging plane of the camera, the 3D coordinate information of the object surface can be obtained. With sub-millimeter measurement accuracy, the sensor is able to clearly capture the subtle features of an object's surface, meeting the requirements of product contour scanning and dimensional measurement. With a measuring range of up to 200mm, the sensor can easily cope with the inspection tasks of various small and medium-sized products. At the same time, the sensor has a high sampling frequency, can quickly complete the data acquisition, and effectively improve the measurement efficiency.

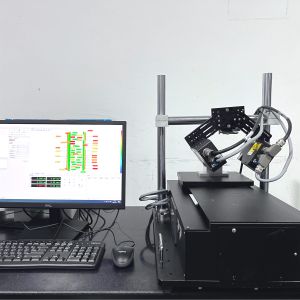

C、Exercise Platform

The motion stage provides precise control of the movement of the object under test and ensures that the sensor is able to fully scan the surface of the object. This program uses a high-precision linear slide with a stepper motor motion platform. The linear slide has a repeatable positioning accuracy of ±0.05mm, which ensures the accuracy and stability of the object's movement during the measurement process. The stepping motor can realize precise speed and position control by controlling the pulse signal, so users can flexibly set the moving speed and path of the object according to the measurement requirements. In addition, the load capacity of the motion platform can meet the weight requirements of most products up to 200mm, ensuring a smooth and reliable scanning process.

System Construction

1. Hardware connection: Fix the 3D contour scanning sensor on a suitable bracket to ensure that it can stably irradiate the measured objects on the moving platform. Connect the sensor with the computer through the data line to ensure the stability of data transmission. At the same time, connect the controller of the motion platform with the computer to realize the control of the platform movement.

2. Software installation and configuration: install the measurement software MetX on the computer and configure the parameters according to the models of the sensor and the motion platform. Set the parameters such as the acquisition frequency and measurement range of the sensor, as well as the parameters such as the moving speed and stroke of the motion platform.

Workflow

-

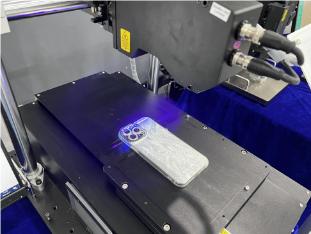

Measurement preparation: Place the object to be measured on the motion platform and adjust the position and attitude of the object to ensure that the sensors are able to scan the surface of the object completely. Set up the measurement tasks in the measurement software MetX, such as selecting the measurement type and defining the measurement area.

-

Data Acquisition: Start the measurement program, the motion platform moves the object according to the preset path, and the 3D contour scanning sensor synchronously acquires the 3D data on the surface of the object. The sensor transmits the collected raw data to the computer in real time.

-

Data processing and analysis: The measurement software MetX processes the collected raw data, removes noise and anomalies, and generates an accurate point cloud model. The software analyzes and calculates the contours and dimensions of the object according to the preset measurement algorithms and generates a measurement report.

-

Output: The user can view the measurement results, including the dimensional parameters of the object, contour graphics, etc., on the interface of the measurement software MetX. Measurement reports can be exported in various formats, such as PDF, Excel, etc., for easy archiving and subsequent processing.

Advantages and Application Scenarios

(A)Program Advantages

-

Cost-effective: The measurement software MetX, the 3D contour scanning sensor and the motion platform are all mature products with relatively low prices, which effectively reduces the system construction costs while meeting the basic measurement requirements.

-

Easy to operate: The simple interface and automated measurement function of MetX, as well as the precise control of the motion platform, make the whole measurement process easy to understand.

-

High measurement accuracy: The sub-millimeter accuracy of the 3D contour scanning sensor and the high-precision positioning of the motion platform ensure the accuracy of the measurement results, which can meet the accuracy requirements of the product appearance contour scanning and dimensional measurement.

(B)Application Scenarios

-

Manufacturing industry: It can be used for dimensional inspection and quality control of components to ensure that the product meets the design requirements. For example, in the production process of cell phone shells, automotive parts, etc., the appearance of the product contour and size of the rapid detection, timely detection of defects in production.

-

Cultural relics protection and reproduction: 3D scanning of small cultural relics to obtain their precise appearance data for cultural relics protection, restoration and reproduction. Through this program, the three-dimensional information of cultural relics can be quickly obtained without damaging them.

-

Education and scientific research: in the teaching and research of universities and scientific research institutions, it is used for three-dimensional modeling of objects, measurement experiments, and so on. The program is easy to use, low cost, and suitable for teaching and research scenarios.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com