In the field of industrial manufacturing and quality inspection, accurate measurement is the key link to ensure product quality and productivity. With the continuous progress of technology, image measurement and traditional contact measurement as two mainstream measurement methods, each with unique technical advantages, play an important role in different application scenarios. How to make the right equipment selection between the two based on actual needs has become an important issue for many enterprises.

Precision Parts Processing Scenario: High-precision Image Measuring Instruments

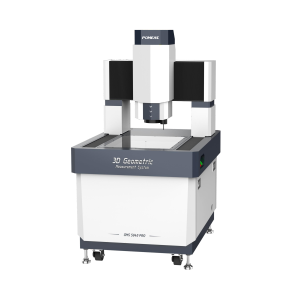

In precision parts processing in aerospace, automotive manufacturing and other industries, the requirements for measurement accuracy are extremely high, often reaching the micron or even nanometer level. Traditional contact measurement, such as coordinate measuring machine, through the probe and the measured object surface direct contact to obtain data, the measurement accuracy can reach ± 0.5μm, in the high-precision measurement has a deep technical accumulation. For example, in the processing of aero-engine blades, the CMM can accurately measure the dimensions and tolerances of complex surfaces of blades with its high precision, which provides a reliable guarantee for product quality.

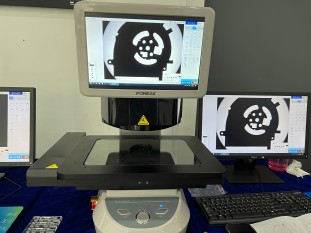

Image measurement, with the help of optical imaging technology and image processing algorithms, to achieve non-contact measurement of the object. Part of the high-end image measurement equipment can also reach micron-level accuracy, and fast measurement speed, can realize the object to be measured by the rapid scanning. In the production of cell phone camera module, the image measuring instrument can be completed in a short period of time on a number of small parts of the size of the accurate measurement, greatly improving production efficiency.

Selection points: in the very high requirements for accuracy, and the shape of the object to be measured rules, the number of less, the traditional contact measuring equipment is the first choice; if you need to a large number of complex shape of the rapid measurement of small parts, image measuring equipment is more advantageous.

Flexible Material Measurement Scenarios: In-Line Densitometer

Flexible materials such as rubber and plastic film are easily deformed when subjected to external forces. The probe contact of traditional contact measurement can cause damage to the material surface, affecting the measurement accuracy and even damaging the sample. The non-contact nature of image measurement makes it stand out in the measurement of flexible materials. For example, in the quality inspection of medical rubber gloves, the image measuring instrument can measure the size and thickness uniformity of the gloves without touching the gloves, which not only ensures the measurement accuracy, but also avoids damage to the product.

Selection points: for flexible material measurement, image measuring equipment because of its non-contact characteristics, become the choice.

In-line production inspection scenarios: In-line image measuring instrument

In modern production lines, real-time and fast inspection of products is required to ensure the continuity of production and the stability of product quality. Traditional contact measurement is difficult to meet the requirements of high-speed production lines due to the relatively slow measurement speed. Image measurement equipment can realize rapid photo and data analysis, can be completed in a very short time on the product measurement and detection. For example, in the electronic component placement production line, image measurement equipment can monitor the placement position and size of components in real time, and once problems are found, an alarm will be issued immediately, which effectively reduces the defective rate and improves production efficiency.

Selection points: In the online production and inspection scenarios, the image measuring equipment with fast measuring speed and real-time data feedback function should be prioritized to meet the requirements of the production line for efficiency and real-time.

Large Workpiece Measurement Scenario: Multi-sensor Measurement System

Shipbuilding, bridge construction and other fields involve the measurement of large workpieces, which are bulky and complex in shape, and the traditional large-scale coordinate measuring instrument, although with high accuracy, has a large equipment size and complex installation and commissioning, making it difficult to meet the on-site measurement needs. Portable contact measuring equipment, such as articulated arm measuring instrument, has a high degree of flexibility, can be measured at the scene of large workpieces, but its measurement range is still limited.

The development of image measurement technology has given rise to large-size measurement systems, such as laser tracking instrument combined with image measurement equipment, which not only has a large measurement range, but also has high accuracy. In the construction process of large ship hull, such equipment can quickly obtain the overall dimensional data of the hull, providing an accurate basis for subsequent assembly and processing.

Selection points: For large workpiece measurement, if the accuracy requirements are high and the measurement site space is limited, you can choose the contact measurement equipment with better portability; if you need a large measurement range and high measurement efficiency, the combination of image measurement and laser tracking equipment is more suitable.

Conservation and Restoration Scenarios: 3D Contour Scanning

In the conservation and restoration of cultural relics, it is necessary to obtain detailed data on the relics without damaging them. Traditional contact measurement may cause irreversible damage to the surface of cultural relics, so it is not applicable. Image measurement technology can realize non-destructive measurement of cultural relics through multi-angle photography and three-dimensional reconstruction technology, and generate high-precision three-dimensional models, providing comprehensive data support for the protection, restoration and digital archiving of cultural relics. For example, in the digital protection of the murals of the Mogao Caves in Dunhuang, the image measurement technology plays an important role in recording the color, texture and morphological information of the murals in a complete way.

Selection points: In cultural relics protection and restoration scenarios, image measurement equipment with non-destructive measurement functions must be selected to ensure the safety and integrity of cultural relics.

In different measurement scenarios, image measurement and traditional contact measurement have their own advantages and disadvantages. Enterprises in the selection of measuring instruments, should take into account the measurement accuracy, the characteristics of the measurement object, production efficiency, measurement environment and other factors, choose the most suitable measurement equipment, so as to improve product quality at the same time, reduce production costs and improve the market competitiveness of enterprises.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com