Measurement Principles and Core Design

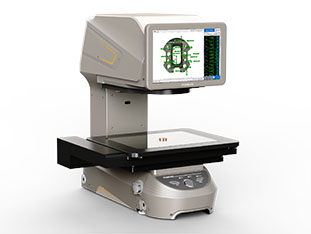

1. Based on the principle of non-contact optical projection, the Image Dimension Measuring Instrument (Flash Measuring Instrument) captures the contour of the measured object through a high-resolution dual telecentric lens and a high-pixel CMOS camera, and quickly analyzes the image data with an intelligent algorithm. Its core feature is “one-button” operation, without complex programming, can measure multiple workpieces at a time; built-in spectral confocal sensor, support for three-dimensional dimensions (such as height) measurement, combined with two-dimensional plane parameters, to achieve multi-dimensional data acquisition.

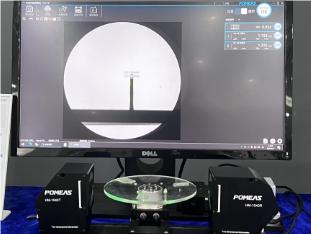

2. On-line projection image measuring instrument adopts dynamic projection technology, through the high-brightness LED light source and low-distortion lens real-time projection of the image of the measured object, combined with high-speed CMOS sensors and adaptive algorithms, can complete the measurement of the workpiece at high speed (such as hundreds of frames per second). Its core is the “real-time online” ability, without downtime can be embedded in the production line; support for automatic correction of positional offset, adapt to vibration, dust and other complex environments, the measurement accuracy of up to 0.08μm.

Measuring Platforms

1. Image dimension measuring instrument: typical platform is 300mm×200mm, suitable for medium and large-sized workpieces (e.g. mechanical parts, injection molding parts);

2. In-line projection measuring instrument: measuring area is φ40mm~φ120mm, suitable for small precision parts (e.g. electronic components, shaft parts).

Application Scenarios

1. Image Dimension Measuring Instrument: focusing on complex shapes and high-precision two-dimensional / three-dimensional measurement, such as mold contour, precision parts tolerance analysis, commonly used in machining, automotive parts quality inspection;

2 Online Projection Measuring Instrument: Designed for real-time monitoring of production lines, suitable for high-speed assembly lines (such as semiconductor packaging, lithium battery production), support for batch duplication of measurement tools to achieve unmanned inspection.

Suggestions for selection

1. Selection of image dimension measuring instrument: If the demand for high-precision off-line inspection of complex workpieces If the demand is for high-precision offline inspection of complex workpieces, or if three-dimensional data (e.g., height, depth) need to be taken into account, and the requirement for measurement efficiency is moderate;

2. Choose on-line projection measuring instrument: if you need to embed high-speed production line real-time monitoring, or Detect tiny parts (such as chip pins, precision shafts), and the environment is complex (vibration, dust).

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com