How do you measure the segment difference of a product? Read this to get started

In the field of industrial inspection, segmentation difference is a crucial index, which is directly related to the assembly accuracy, appearance quality and performance of the product. So, what is the segment difference? How to accurately measure segmentation? How can POMEAS measurement solutions and equipment help?

Segmental difference refers to the position of the parting surfaces of two mold inserts or front and rear molds because of the deviation in machining accuracy. In industrial manufacturing, the existence of segment difference will directly affect the assembly accuracy and appearance quality of the product. For example, in automobile manufacturing, if the segment difference between the door and the body is too large, it will not only affect the overall aesthetics of the vehicle, but also may lead to poor sealing of the door, increased noise and other problems. Therefore, accurate measurement and control of the segment difference is crucial for improving the quality of industrial manufactured goods.

Difficulties in measuring segment differences

1、Segmental differences often exist in tiny parts of the product, requiring high-precision measuring equipment to accurately capture;

2、Because of the wide variety of industrial manufactured goods and their different shapes, the specific shape and size of the product need to be taken into account when measuring the segment difference;

3、Environmental factors during the measurement process, such as temperature and humidity, may also have an impact on the measurement results.

Segment Differential Measurement Program:

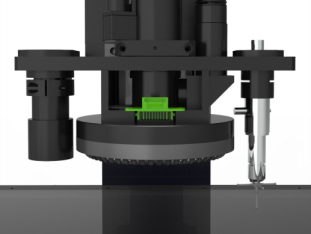

1. Spectral Alignment Vision Measurement Solutions

POMEAS' Spectral Alignment Vision measurement solution utilizes a unique alignment structure design that allows for non-contact measurement. This measurement method ignores the material of the product and avoids possible damage or contamination caused by contact, ensuring reliable and repeatable measurements. By combining image measuring components with spectroscopic technology, this solution can realize fast positioning and high-precision measurement of products. Especially for the measurement of segment differences in tiny parts such as wafers, POMEAS' spectral alignment vision measurement solutions have shown excellent performance.

2. High Precision Image Measuring Instrument

POMEAS also produces a series of high precision image measuring instruments such as IMAGE3 PRO-H, IMAGE3 MAX, IMAGE3 MAX2 and other models. These gauges are available in a variety of measurement ranges and accuracy levels to meet the needs of different industrial manufacturing products. When measuring segment differences, these gauges can accurately capture minute deviations on the product surface through high-precision image acquisition and processing technology, providing reliable data support for quality control.

3. Advanced measurement algorithms and software

In addition to the hardware equipment, POMEAS has developed advanced measurement algorithms and software. These algorithms and software are able to efficiently process and analyze the collected measurement data to quickly generate segment difference measurement results. At the same time, POMEAS measurement software has an intuitive and easy-to-use interface and powerful data processing functions, enabling operators to quickly get started and efficiently complete measurement tasks.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com