Surface inspection is critical in manufacturing, especially for complex parts such as automobile bodies and aircraft engine blades. There are a variety of measurement methods that need to be selected according to specific needs.

Contact Testing

1. Coordinate Measuring Machine (CMM): mechanical probes contact the surface point by point to obtain 3D coordinate data; high accuracy (up to ±0.5μm), suitable for complex internal cavities and a small number of parts with characteristic curves; slow speed, may damage soft surfaces, manual intervention is required.

2. Contour meter method: scan the contour line by line and splice it into surface data; the efficiency is higher than that of CMM, and it can measure convex and concave surfaces; the speed is still slow, and it is only suitable for surfaces with small gradient changes (local gradient deviation <5°), and the splicing error affects the accuracy.

Non-contact detection

1. Optical measurement technology

① Structured light scanning: projected grating pattern, use the deformation pattern to reconstruct the three-dimensional shape; faster, suitable for complex surfaces; affected by ambient light, surface reflection characteristics.

② Laser scanning: laser beam scanning, through the reflected light time difference or phase difference calculation of the surface shape; high precision, suitable for large-size workpieces; high cost of equipment, sensitive to the environment.

③ Interferometry: using light wave interference principle to measure the surface shape; high precision (nanometer level), suitable for optical components; strict requirements on the measurement environment.

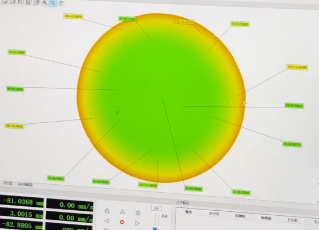

2. Schack-Hartmann wavefront detection method: analyze microlens imaging spot offset; real-time measurement, large dynamic range; limited lateral resolution, accuracy affected by spot overlapping.

3. Image measuring instrument: optical imaging combined with image processing; suitable for metal, glass and other high-reflectivity surfaces; for low reflectivity or opaque materials (such as rubber, plastic) accuracy drops.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION