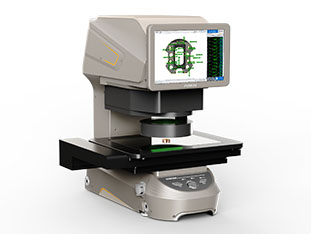

The advantages of a one-button image measuring instrument (also known as a flash meter) as a quality inspection tool for the modern manufacturing industry can be summarized as “Fast, Accurate, Simple and Intelligent”.

A、Lightning measurement speed, overturning traditional efficiency

- Batch inspection capability: a single measurement can cover all parts in the field of view (up to 512 measurement points), speed up to 81mm/s, 100 samples / batch inspection of the total time consumed <5 minutes, the efficiency compared with the traditional quadratic measuring instrument to improve several times.

- One-key second measurement: support 1 second measurement of 100 parts, CNC mode can automatically locate and measure a number of parameters of complex parts (such as the length, width and curvature of the center frame of cell phones), without the need to manually adjust the focus or displacement scale.

B、Micron-level accuracy, stable and reliable

- Sub-pixel Algorithm Enhancement: Adopting 20 megapixel CMOS camera + dual telecentric lenses, combined with sub-pixel subdivision technology (accuracy up to 0.1 pixel), it can detect micrometer size (e.g., 0.005mm/pixel) to meet the stringent requirements of precision parts (e.g., miniature sensors).

- Environmental anti-interference: the optical scale is not affected by temperature and humidity, with a repeatability of ±0.5μm, far exceeding traditional calipers and quadratic measuring instruments, and with higher long-term measurement stability.

C、Minimal operation, zero threshold to start

- One-key flash measurement: support CAD drawing import, the instrument automatically identifies the measurement part, no fixture positioning, any placement can be realized “foolproof” operation.

- Intelligent calibration: automatic focus + non-linear error correction, eliminating human interference, to ensure that the results of different operators are consistent, without the need for professional skills training.

D、Non-contact measurement, non-destructive safety

- Non-destructive testing: Avoid contact damage through optical imaging, especially suitable for deformable parts (e.g., thin-walled injection molded parts), complex curved surfaces (e.g., turbine blades), and high-precision parts (e.g., semiconductor wafers).

- Multiple light source modes: Projected light, coaxial light and other modes are provided to clearly capture contours, steps, chamfers and other features, solving the problem of low-contrast measurement.

E、Powerful software, data-driven decision making

- Automatic Report Generation: Automatically generate Excel/SPC report after measurement, support remote data output, seamlessly connect to production management system.

- Advanced analysis tools: Provide 80+ extraction tools (e.g. feature extraction, shape and location tolerance analysis), support data statistics and process control, help quality optimization.

F、Broad adaptability, cross-cutting coverage

- Multi-scenario applications: from mechanical parts (gears, screws) to electronic components (capacitors, connectors), to cultural relics measurement (pottery size recording) and biomedical (micro instruments inspection), all can be accurately performed.

- Customized service: Supporting CNC mode, we can customize the measurement solution for specific needs (e.g., multi-stage diameter measurement of automotive crankshafts) and realize 2.5D complex parameter inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com