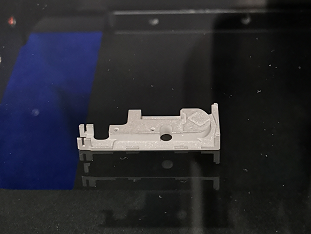

Image measuring instrument can cover plastic/metal/rubber full material measurement

Measuring different material difficulties:

The traditional means of measurement in the face of plastic, metal, rubber and other types of material workpiece, often problematic.

1, plastic material, because of its soft texture, the ordinary gauge a little careless will leave indentation, affecting the subsequent use, and easy to measure due to uneven force caused by dimensional deviation, precision is difficult to guarantee.

2, although the hard texture of the metal material, but the complexity of the shape and small tolerances, making it difficult to accurately measure the key dimensions of the traditional measuring tools, the range of error often exceeds the standard.

3, rubber material due to its elasticity and flexibility, in the measurement process is very easy to deformation, resulting in poor repeatability of the measurement results, the error is difficult to control.

The IMAGE series of POMEAS one-button image measuring instruments breaks through these traditional dilemmas. Whether it's the deformable curves of soft rubber, the hard edges of metal workpieces, or the intricately designed structures of plastic parts, all the operator has to do is press a single button, and the instrument responds quickly to output high-precision measurement data.

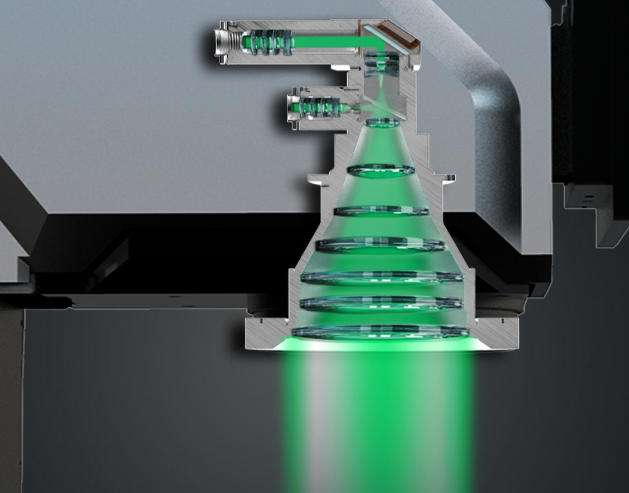

The outstanding performance of the IMAGE series cannot be separated from its core configuration of a 20-megapixel dual telecentric lens. The lens utilizes the principle of parallel optical path design, which fundamentally eliminates the problem of imaging aberration, and can truly restore the actual contour of the workpiece. With the advanced micron-level edge-grabbing algorithm, even the slightest difference in contour, such as 0.001mm, can be recognized accurately.

In the production of precision metal gears, the IMAGE series of POMEAS measuring instruments can easily measure the critical tooth pitch to ensure the smoothness and accuracy of the gear transmission.

In the manufacture of flexible rubber seals, the instrument can also accurately control the measurement of the inner diameter, a critical dimension, to ensure the sealing performance of the seal.

From metal parts processing in the aerospace field to the production of plastic and rubber parts in daily necessities, all kinds of material workpieces under the IMAGE series of measuring instruments can obtain reliable data as accurate as 1μm, which can truly realize the efficiency and accuracy of multi-material mixed line inspection, and bid farewell to the traditional measurement of the different materials to be picky about the situation.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION