In the automotive, aerospace, precision machinery and other fields, the surface quality of metal processing parts directly affect the reliability and service life of the product. Traditional manual visual inspection or contact inspection methods are inefficient, poor accuracy, and difficult to meet the needs of high-precision manufacturing.FA lenses (industrial automation lenses) have become the core tool for metal surface scratch detection by virtue of their high resolution, low distortion, and resistance to environmental interference.

Technical Challenges in Scratch Detection on Metal Surfaces

Surface scratches on machined metal parts (e.g., aluminum alloy wheels, stainless steel cutting tools, titanium alloy aerospace components) have the following characteristics:

1、Complex shape: the width of the scratch can be as fine as 0.01mm, the depth varies greatly, and is often accompanied by reflections and shadows interference;

2、Environmental harshness: workshop oil, dust and strong light can easily lead to blurring of the image, which affects the accuracy of the detection;

3、Efficiency needs: the traditional manual inspection is slow, and it can't meet the requirements of real-time inspection of high-speed production lines.

FA lens through the optical design optimization and intelligent algorithm synergy, break through the above bottlenecks, to achieve the accurate capture of the metal surface micro-scratches.

Core technical advantages of FA lenses

1. Telecentric Optical Path Design: Eliminate Parallax and Aberration

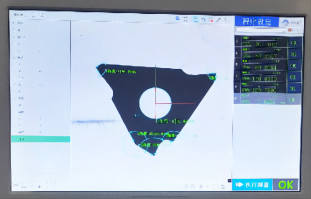

POMEAS FA lens adopts telecentric optical path, which ensures that the main light rays are parallel to the optical axis and eliminates the dimensional error caused by the change of object distance. Combined with the aspherical lens group, the aberration rate is controlled within 0.01%, which ensures the high precision measurement of the width and length of scratches (error ≤ ±1μm). 2.

2. High Dynamic Range Imaging: Responding to Complex Reflective Scenes

Reflections on metal surfaces can easily lead to overexposure or dark corners. POMEAS FA lens is equipped with dynamic aperture control and multi-spectral filtering technology, which can adaptively adjust the amount of incoming light, while filtering stray light, and clearly presenting the details of the edge of the scratches.

3. Wide Depth of Field Coverage: Adapting to 3D Surface Structures

Surfaces of machined metal parts may have unevenness (e.g. forged texture, weld marks). The POMEAS FA lens maintains sufficient depth of field at high magnification through depth of field enhancement technology, ensuring clear imaging of scratches on curved surfaces, steps and other complex areas.

Scenario applications for FA lenses

1. Automotive Wheel Inspection: Improving Yield and Production Efficiency

-

Inspection efficiency: single hub inspection time is shortened from 8 seconds to 2 seconds, supporting high-speed operation of production lines;

-

Accuracy upgrade: identifying scratches of 0.02mm width, and the leakage rate is reduced from 5% to 0.3%;

-

Cost optimization: reducing the loss of manual re-inspection and scrapping, with an annual cost saving of more than 2 million yuan.

2. Tool Edge Inspection: Guaranteeing Cutting Performance

-

Identification of microscopic defects: Detection of 0.01mm micro chipping and edge burrs;

-

3D Morphological Analysis: Reconstructs the depth of scratches and evaluates the degree of tool wear through multi-view imaging.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com