Application of zoom lens in automated inspection of machined parts

With the wave of intelligent manufacturing sweeping the world today, industrial inspection technology is experiencing a leapfrog upgrade from “manual sampling” to “full-process automation”. As the core component of industrial vision system, zoom lens has become the key technical support for realizing full-size and full-defect inspection of machined parts by virtue of its flexible varifocal, high-precision imaging and intelligent adaptation capability.

Traditional industrial inspection relies on fixed focal length lenses that need to be changed frequently to accommodate different sized workpieces, which is inefficient and costly. With continuous zoom technology, zoom lens can realize magnification switching in milliseconds without the need to physically change the lens, which significantly simplifies the inspection process. Equipped with high-precision optical design and intelligent control algorithms, POMEAS zoom lens supports a magnification range of 0.1X-200X. Together with the high-resolution sensor, it can clearly capture minute defects (e.g., scratches and burrs under 0.01mm) while maintaining image clarity and color reproduction.

Multi-scene applications for zoom lenses

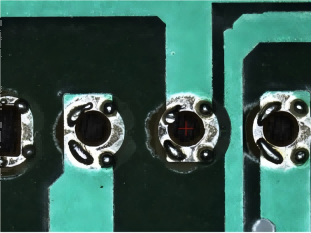

1. Electronic component inspection: precision control of tiny dimensions

In the production of electronic components such as semiconductors, PCBs, connectors, etc., the size of the components is very small (e.g. chip pin spacing < 0.5mm) and the types of defects are complex (soldering, contamination by foreign objects, etc.). POMEAS zoom lens through the high-magnification zoom and telecentric optical path design, to achieve a comprehensive inspection of the component surface, structure and assembly precision. For example: chip package inspection: fast switching of magnification, detection of solder ball coplanarity, gold wire bonding defects; FPC flexible board inspection: high precision identification of line shorts, circuit breaks and tiny copper foil bumps.

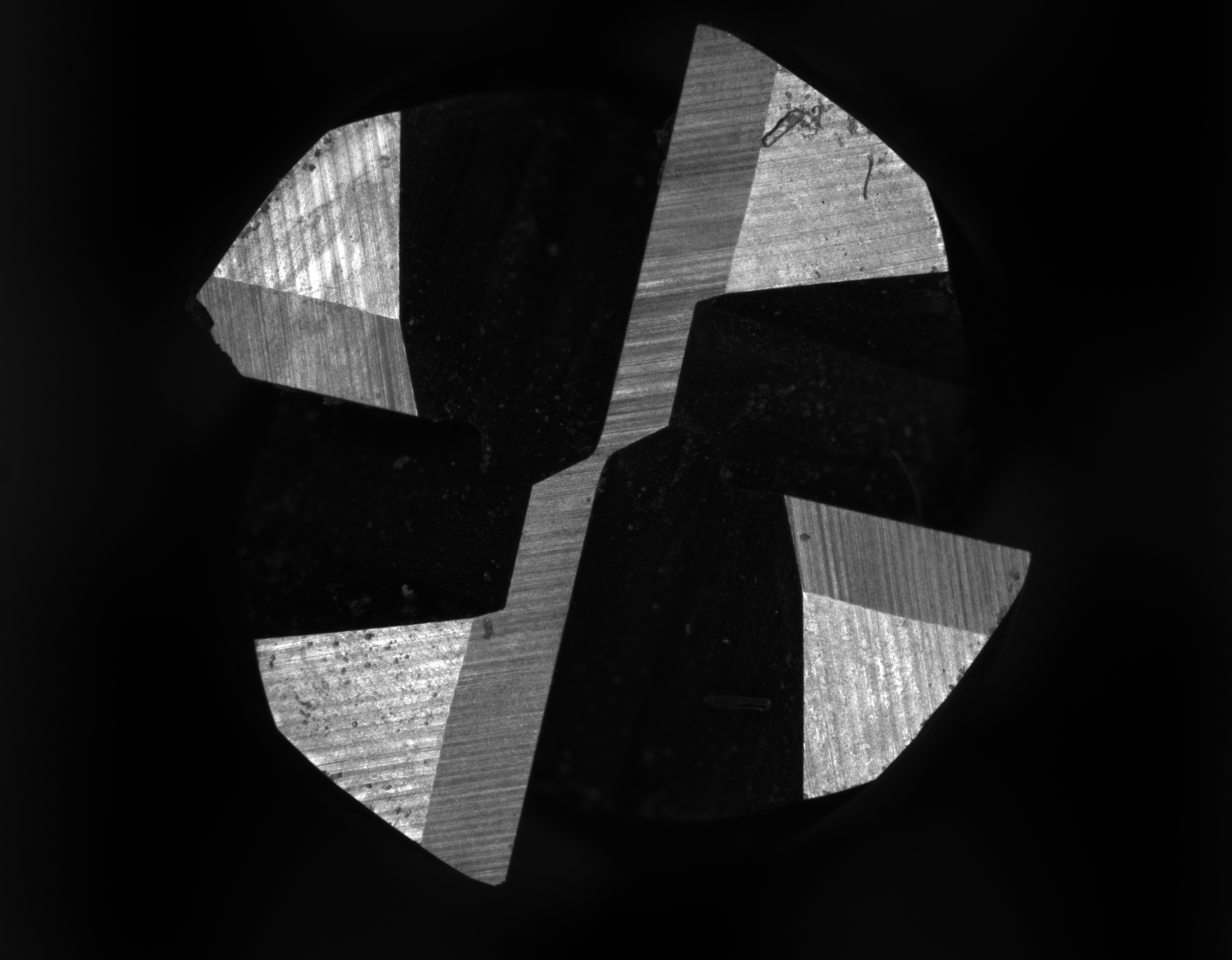

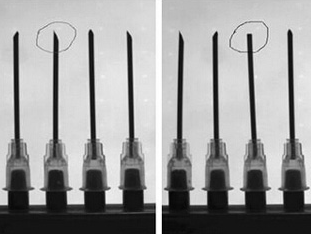

2. Inspection of precision mechanical parts: efficient adaptation of multiple dimensions

Precision parts (e.g. gears, bearings, screws) in aerospace, medical equipment and other fields are characterized by multiple specifications and features. POMEAS zoom lens supports automatic magnification memory and multi-station simultaneous inspection, and can switch inspection parameters with one key, compatible with different sizes of workpieces. For example: gear inspection: measuring tooth shape, tooth pitch and runout error at the same time; syringe needle inspection: freely switching between 0.1X-50X magnification to accomplish multi-dimensional inspection of needle tip sharpness, lumen diameter and so on.

3. Automotive parts testing: reliability verification under complex working conditions

Automotive manufacturing involves high-intensity, high-precision inspection needs (e.g., engine block sealing, headlight optical performance). POMEAS zoom lens adopts IP67 protection design, which can adapt to harsh environments such as oil, dust, etc., and realize in-motion inspection through dynamic focusing technology. For example: wheel inspection: high-speed scanning of rim size and spoke welding quality; light distribution inspection: combined with spectral analysis to accurately assess light pattern distribution and illumination uniformity.

Advantages of zoom lens

-

High Resolution: Using high quality optical glass and precision processing technology to ensure clear and sharp images.

-

Low distortion: Effectively control lens distortion to ensure measurement accuracy.

-

Long Working Distance: Provides a longer working distance for easy installation and use.

-

Ruggedized: metal casing and sealed design, adaptable to a variety of harsh industrial environments.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com