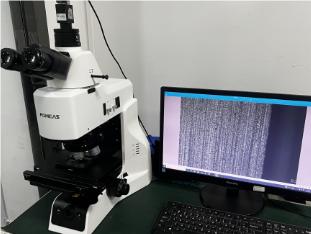

Explore the microscopic world with the POMEAS Ultra-Depth-of-Field Metallurgical Microscope

In the fields of material science, metal processing and electronics manufacturing, the observation and analysis of microstructure is the key to ensure product quality and performance. In order to meet this demand, POMEAS has launched the new Super Depth of Field metallographic microscope, which not only has excellent optical performance, but also has super depth of field capability, which can help users easily capture every detail of the microscopic world.

Q: Why do you choose POMEAS super depth of field metallurgical microscope?

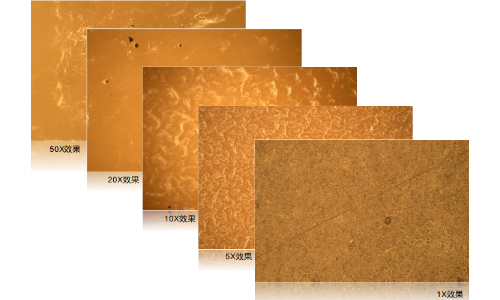

1. Superior Depth of Field, Clearly Presenting Three-Dimensional Structures

Conventional microscopes often have difficulty in maintaining the clarity of the entire field of view when observing uneven samples. The POMEAS Super Depth of Field microscope, with its advanced optical design and intelligent depth of field extension technology, is able to maintain a large depth of field at high magnification, ensuring that every detail of the sample surface can be clearly presented, which is especially suitable for observing complex three-dimensional structures.

2. High resolution, details at a glance

With high-quality optics and advanced imaging system, POMEAS super depth of field metallurgical microscopes are able to provide extremely high resolution, making even micron-sized fine structures clearly visible. Whether it's metal grains, cracks, or coating surfaces, they can all be accurately captured.

3. Intelligent operation to enhance work efficiency

The microscope is equipped with an intelligent focusing system and image processing software. Functions such as auto-focusing, image stitching and depth of field synthesis greatly simplify the operation process, so that even complex samples can be analysed quickly.

4. Multi-functional application to meet diversified needs

POMEAS super-depth-of-field metallographic microscope is not only suitable for metallographic analysis of metal materials, but also widely used in ceramics, semiconductors, composite materials and other fields. Whether it is a research laboratory or industrial production site, it can provide users with reliable microscopic observation solutions.

5. Humanised design, more convenient to use

The microscope adopts an ergonomic design, so it will not feel fatigue even after long time use. Meanwhile, the modular structure design makes maintenance and upgrading more convenient, and users can flexibly configure different accessories and functions according to their needs.

Application Scenarios

-

Metallic material analysis: Observation of grain structure, phase transitions, cracks, etc. of metals to assess material properties and processing quality.

-

Electronic Component Inspection: Check the microstructure of circuit boards, chips and other electronic components to ensure product reliability.

-

Research and Education: Provide universities and research institutions with high-precision microscopic observation tools to help academic research and teaching.

-

Quality control: In industrial production, rapid detection of defects and microstructure on the surface of products to ensure product quality.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com