In the field of spectral confocal measurements, the SFS-C8000 controller has excellent performance parameters and flexible function configurations. Its modular design and open interfaces provide flexible solutions for industrial automation.

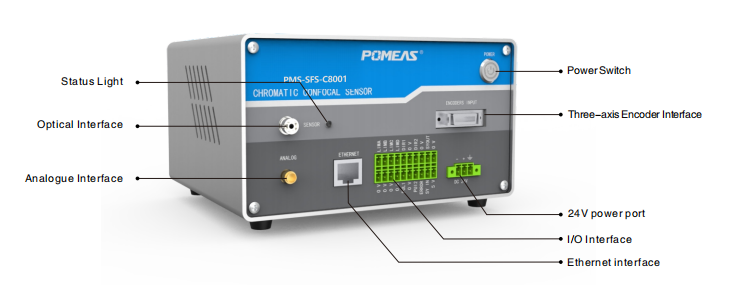

SFS-C8000 Spectrum Controller Display

1. Dual-channel parallel processing system: adopting dual fiber optic channel design, it can drive two probes for synchronous measurement at the same time, breaking through the efficiency bottleneck of traditional single-channel equipment. Combined with XYZ grating displacement system, it can realize ±0.1μm positioning accuracy and build 3D spatial measurement network.

2. Intelligent motion control module: Built-in 1-2 way motor trapezoidal acceleration and deceleration control algorithm, support sweep point cloud measurement mode, can realize high-speed data acquisition of 5000 sampling points per second. This dynamic scanning ability makes it show its unique advantage in complex surface measurement.

3. Multi-physical quantity fusion interface: Equipped with analog output channels, it can be seamlessly connected to precision actuators, such as piezoelectric actuators, to build a closed-loop control system. The 0.1nm resolution analog signal output provides a reliable guarantee for nanometer precision control.

SFS-C8000 Spectrum Controller Applications

1. 3D Topography Measurement System: Based on the principle of spectral confocal, it can realize 3D surface topography reconstruction with 0.1μm vertical resolution. Through the self-developed point cloud data processing algorithm, 26 key parameters such as surface roughness and flatness can be generated quickly.

2. Non-transparent material thickness measurement technology: Adopting the opposed-radiation measurement architecture, breaking through the limitations of traditional contact thickness measurement. It can realize the thickness measurement of multi-layer structure with 0.5μm thickness resolution, which is especially suitable for the inspection of materials with low light transmittance, such as glass and ceramics.

3. Multi-test head cooperative measurement: through the independent dual fiber optic channel, support multi-test head synchronous work. In automotive parts inspection, it can simultaneously complete the composite measurement of surface profile and dimensional tolerances, increasing the inspection efficiency by more than 40%.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION