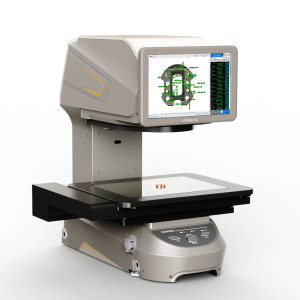

In today's industrial manufacturing, precision and efficiency are the two core pursuits. In order to meet this demand, a variety of high-tech inspection equipment has emerged, among which the image measuring instrument IMAGE 3 Pro with its excellent performance and a wide range of applications, has become the industrial inspection of the “all-rounder”. What can the IMAGE 3 Pro measure? And what are its unique features?

Measurement capabilities of IMAGE 3 Pro

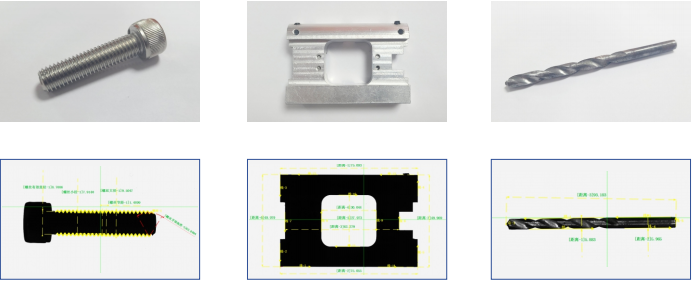

The IMAGE 3 Pro Image Gauge is a state-of-the-art inspection device that combines high accuracy, high efficiency and ease of operation. It has an extremely wide measuring range, covering virtually all dimensions and shapes that need to be measured accurately in industrial manufacturing. Whether it's basic dimensions such as distances, radii, angles, radians, or more complex geometries and contours, the IMAGE 3 Pro handles them all with ease.

Specifically, IMAGE 3 Pro can measure the dimensions and shapes of a wide range of workpieces such as stamped and molded parts, injection molded parts, and laser cut parts. It plays an important role in many industries, including automotive, electronics, plastic parts, hardware, and semiconductors. For example, in automotive manufacturing, IMAGE 3 Pro can be used to check the dimensional accuracy and assembly quality of parts, while in the electronics industry, it can be used to measure the size and position of tiny components such as PCB boards and chips.

Product Features of IMAGE 3 Pro

1. High-precision measurement: IMAGE 3 Pro adopts self-developed double-magnification double-side telecentric optics with high telecentricity and low distortion characteristics, which enables high-precision measurements even in the presence of segmental aberrations. Its measurement accuracy is up to ±3μm, which meets the stringent requirements for accuracy in most industrial manufacturing.

2. Fast Measurement: IMAGE 3 Pro supports one-button fast measurement. After placing the measurement object, just press one button to start the measurement and get accurate results in a short time. It is extremely fast, measuring up to 100 parts in one second, which greatly improves inspection efficiency.

3. Easy to Operate: The IMAGE 3 Pro has an easy-to-understand interface and requires no specialized training to operate. It supports automatic recognition of the measurement area and direction, eliminating the need to position the measurement object and origin, greatly simplifying the measurement process.

4. High Stability: IMAGE 3 Pro has an automatic anomaly filtering function that effectively eliminates interfering factors during the measurement process, ensuring the accuracy and stability of the measurement results. The IMAGE 3 Pro also supports autofocus, eliminating the effects of uneven focus on measurement results.

5. Versatility: In addition to basic dimensional measurements, IMAGE 3 Pro also supports virtual line and virtual point measurements, as well as the switching of multiple measurement modes. In addition, it supports simultaneous measurement of multiple products, greatly improving inspection efficiency and reducing costs.

6. Wide Compatibility: IMAGE 3 Pro has a maximum measuring range of 300x200mm and supports cameras compatible with up to 2/3-inch target surfaces. This allows it to adapt to the measurement needs of different sizes and types of workpieces with a wide range of compatibility.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com