In the field of industrial vision inspection, the choice of optical lens magnification is a crucial decision point, which directly affects the accuracy, efficiency and cost of inspection. Faced with a wide range of lens magnification on the market, such as 6.5X, 8X, 12.5X, 14X, etc., many users can't help but ask: is the larger the magnification the better?

Relationship between magnification and field of view

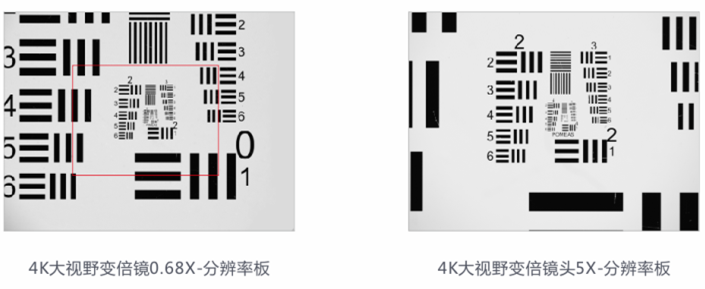

The larger the magnification, the smaller the field of view that the lens can capture, but accordingly, the details of the observed object will be magnified more clearly. Conversely, the smaller the magnification, the larger the field of view, but the detail performance is relatively blurred. Therefore, when selecting a lens magnification, the field of view and detail clarity must be weighed against the specific inspection needs.

Application Scenarios and Limitations of High Magnification Lenses

High-magnification lenses, such as 12.5X, 14X, etc., play an irreplaceable role in inspection tasks that require extremely high precision. For example, in fields such as semiconductor chip inspection and precision machining, high-magnification lenses are able to capture minute defects and details to ensure product quality. However, high-magnification lenses also have obvious limitations. Due to the small field of view, the inspection process requires frequent movement of the lens or workpiece, which not only increases the inspection time, but also may introduce positioning errors. In addition, high-magnification lenses require more supporting equipment such as light sources and cameras, increasing system costs.

Advantages of Low Magnification Lenses and Applicable Scenarios

In contrast, low magnification lenses such as 6.5X and 8X are more advantageous when a large area needs to be inspected quickly or for initial screening. They can provide a wider field of view, quickly locate the target object and improve detection efficiency. At the same time, low magnification lenses have relatively low requirements for light sources and cameras, helping to reduce system costs. However, in scenarios that require high-precision inspection, low-magnification lenses may not be able to meet the requirements.

How to choose the right magnification

Choosing the right lens magnification requires consideration of a number of factors, including the accuracy requirements of the inspection task, the speed of the inspection, the size of the workpiece, the conditions of the light source and the cost budget. For the need for high-precision inspection of small-sized workpieces, high-magnification lens may be a better choice; for the need for rapid detection of large areas or preliminary screening tasks, low-magnification lens is more appropriate.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com