How to realise the integrated measurement of flat and curved plastic parts?

In the field of industrial plastic production, product quality control is crucial. After the plastic parts are moulded, the precise inspection of their dimensions and curvature becomes the key link to determine whether the products are qualified or not.

In the traditional inspection process, for the measurement of plastic parts plane and arc, often need to use a variety of different measuring tools and methods, which not only consumes time and manpower, but also due to the differences in measuring equipment and means, the consistency and accuracy of the measurement data is difficult to ensure. In plastic factories, a large number of products need to be inspected quickly and accurately to ensure production efficiency and product quality, at this time a system that can realise the integrated measurement of the plane and arc of plastic parts is particularly necessary.

POMEAS' multi-sensor measurement systems provide the perfect solution to the challenges of measuring plastic parts.

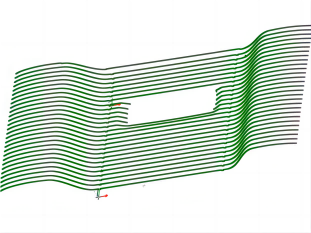

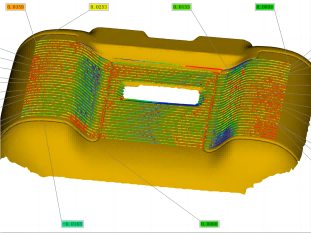

The system combines 2D dimensional inspection, 3D contour scanning and measurement software with powerful measurement functions. 2D dimensional inspection is able to accurately measure the dimensional parameters of the flat part of a plastic part, whether it is the length, width or aperture, etc., and present them with high precision. 3D contour scanning technology plays a key role in the detection of curved parts, which can quickly and comprehensively obtain the contour information of the curved surface of the plastic parts, and through complex algorithms to convert the scanning data into accurate radian values.

The measurement software is at the heart of the system, integrating and analysing the data. It is able to summarise the data obtained from 2D dimensional inspection and 3D contour scanning and compare it with pre-set qualification standard parameters. Operators can quickly and intuitively find out if a product is acceptable by simply operating the software interface. Once the product size or curvature is found to be out of the permissible error range, the software will immediately issue an alarm and provide detailed deviation data, which is convenient for production personnel to adjust the production process in a timely manner to avoid a large number of unqualified products.

The POMEAS Multi Sensor Measurement System offers unrivalled advantages in the integrated measurement of flat and curved plastic parts. It greatly improves the measurement efficiency. Inspection tasks that used to take hours or even days to complete can now be completed in just a few minutes with the help of this system. At the same time, the high-precision measurement data effectively guarantee the product quality, reduce the rate of defective products, for industrial plastics factories to save production costs and enhance market competitiveness.

Measurement results are shown:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com