Advantages of Spectral Confocal Sensor SFS-8022 in Industrial Inspection

In the field of industrial inspection, accuracy and efficiency are always the core objectives. The Spectral Confocal Sensor SFS-8022 revolutionizes industrial inspection with its outstanding performance and demonstrates a number of significant advantages.

High-precision measurement and strict quality control

The SFS-8022 Spectral Confocal Sensor utilizes advanced spectral confocal technology to achieve ultra-high precision measurements at the sub-micron level, based on the principle that light of different wavelengths will fall at different distances when focused. Its working principle is based on the fact that light of different wavelengths falls at different distances when focused, and by precisely analyzing the spectral composition of the reflected light, the position, size and other key parameters of the measurement target can be accurately determined.

In the automotive manufacturing industry, SFS-8022 can accurately measure dimensions such as the bore diameter of the engine block and the diameter of the piston to ensure that each component meets the tolerance range required by the design, guaranteeing stable power output, good fuel economy and high reliability of the engine. In the aerospace field, the manufacturing accuracy of key components such as airplane wings and engine blades is critical to flight safety.

The SFS-8022 is capable of measuring the complex surfaces of these components with high precision and detecting even the smallest dimensional deviations or surface defects, providing a solid guarantee for the high quality of aerospace products. This high-precision measurement capability effectively reduces the defective rate, improves product quality, and reduces after-sales costs and corporate reputation loss due to quality problems.

Fast measurements to speed up production processes

In the fast-paced production environment of modern industry, the speed of inspection has a direct impact on production efficiency, and the SFS-8022 has a fast measurement response time that enables it to complete the inspection of the target object in an instant. Its efficient data acquisition and processing system makes the measurement process smooth and rapid, and can meet the real-time inspection needs of high-speed production line.

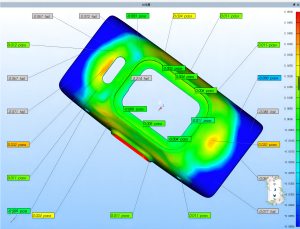

In the production line of cell phones and tablet PCs, which require a large number of components to be inspected for dimensional accuracy and quality screening, the SFS-8022 can quickly measure the dimensional accuracy of the cell phone casing, the thickness of the screen glass, and the position of the internal circuit board components, and give the results of the inspection in a very short period of time to ensure the efficient operation of the production line, and to avoid the bottleneck of the production due to the time-consuming inspection process.

In the food packaging industry, which also requires fast and efficient dimensional and sealing testing of packaging containers, the SFS-8022 can quickly scan the dimensions of packaging bottles and cans to determine whether they comply with the standards, and at the same time, it can test the sealing condition of the packaging to ensure the quality and safety of the food during the shelf life, which greatly improves the efficiency and quality of the packaging production.

Non-contact measurement to protect products and equipment

Traditional contact measurement methods may cause scratches, abrasions and other damages to the product surface during the inspection process, affecting the appearance and performance of the product, especially for products with sensitive surfaces, soft texture or high precision.SFS-8022 adopts a non-contact measurement method, which does not need to be in direct contact with the object to be measured, and acquires the measurement data at a long distance through the optical principle.

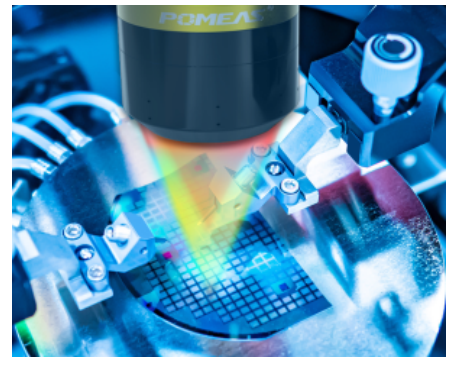

In semiconductor chip manufacturing, the chip surface is extremely delicate and fragile, any small contact damage may lead to chip failure, SFS-8022 can accurately measure the chip's circuit line width, chip thickness, and chip surface flatness and other parameters without touching the chip, to protect the chip from damage and ensure the yield of chip manufacturing.

In the glass manufacturing industry, for the thickness and flatness inspection of glass products, the non-contact measurement of SFS-8022 avoids scratches caused by contact and ensures that the surface quality and optical properties of glass products are not affected. This non-contact measurement not only protects the product being measured, but also reduces wear and tear on the measuring equipment, lowering maintenance costs and extending equipment life.

Adapt to complex environments and expand detection applications

The SFS-8022 spectral confocal sensor has excellent environmental adaptability and can work stably in various complicated environments, such as high temperature, high pressure, high humidity, strong electromagnetic interference, etc. The SFS-8022 can measure the size of steel billets in real time under high temperature environment, which is a great test for the inspection equipment.

In the iron and steel smelting industry, where high temperatures and dusty environments are a great test for inspection equipment, the SFS-8022 can measure the dimensions of steel billets in real time under high temperature environments, providing accurate data for the rolling process in the iron and steel production process to ensure that the dimensional accuracy of steel meets the standards. In chemical production, there are strong corrosive gases and liquids, SFS-8022 can accurately detect the wall thickness of chemical pipelines and the dimensions of valves by virtue of its good protective design and stable optical performance to ensure the safe operation of chemical production equipment.

In the electronic manufacturing workshop, there is a lot of electromagnetic interference, SFS-8022 is not affected by electromagnetic interference, stable detection of electronic products, to ensure the accuracy of the test results. Its wide range of environmental adaptability makes it possible to perform excellent detection performance in different industrial scenarios, expanding the scope of industrial inspection applications.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com