Advantages of measuring threads with an in-line image measuring instrument

In modern manufacturing, threads, as an important part of the connecting parts, the accuracy of their size and shape is directly related to the quality and performance of the product. Therefore, it is crucial to measure the threads accurately.

A. high accuracy of non-contact measurement

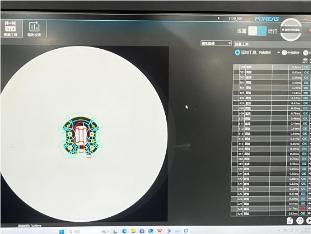

The in-line image measuring instrument adopts the non-contact projection imaging principle, combined with high-precision image analysis algorithms, and is capable of realizing accurate measurement of threads. This type of measurement avoids the errors caused by contact with traditional contact measuring tools (e.g. thread gauges, vernier calipers, etc.), such as deformation and wear caused by the measuring force, and thus significantly improves the accuracy and stability of the measurement. The accuracy of in-line image gauges can often reach the micron level or even higher, which is crucial for the measurement of precision parts such as threads.

B. automation and efficiency

Traditional thread measurement methods often require manual operation, including steps such as adjusting the measuring tool and reading the measurement data, which is not only inefficient, but also may lead to measurement errors due to human factors. In contrast, the in-line image measuring instrument, through its automation function and image processing technology, is able to quickly capture the thread profile and compare it with the preset standard image or data, so as to calculate the size and shape parameters of the thread. This automated measurement greatly improves the measurement efficiency and reduces human error, making thread measurement faster, more accurate and reliable.

C. flexibility and adaptability

online image measuring instrument has a high degree of flexibility and adaptability. It can adjust parameters according to different thread types and measurement needs, such as changing the intensity of the light source, adjusting the camera focal length, etc., to ensure the best measurement results. In addition, it can be equipped with a variety of measurement tools and software functions to meet the needs of different industries and application scenarios. This flexibility makes the online image measuring instrument have a wide range of application prospects in thread measurement.

D. real-time and data traceability

Inline Image Measuring Instrument is capable of real-time measurement and data recording, which is crucial for quality control in the production process. It can seamlessly access the production line for real-time monitoring and measurement of threaded parts to ensure the consistency and stability of product quality. At the same time, it can provide detailed data reports and historical records for subsequent data analysis and traceability. This real-time and data traceability helps companies realize lean production and continuous improvement.

E. reduce human intervention and error

Traditional thread measurement methods often rely on the operator's skills and experience, and are susceptible to the influence of human factors. And online image measuring instrument through automated measurement and image processing technology, greatly reducing human intervention and error. It adopts advanced algorithms and image processing technology to automatically recognize and measure the size and shape parameters of threads, thus improving the accuracy and consistency of measurement.

F. wide Application Areas

In-Line Image Measuring Instrument is suitable for the measurement of various thread types and sizes, including internal threads, external threads, pipe threads and so on. At the same time, it is also widely used in machinery, electronics, automotive, aerospace and many other industries. This wide range of applications makes the In-Line Image Measuring Instrument one of the most important tools in the field of thread measurement.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com