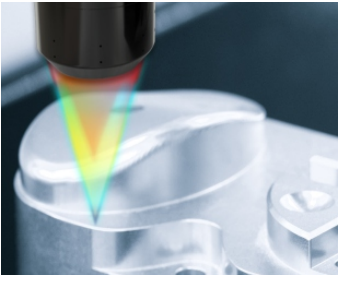

In the field of industrial automation, accurate and efficient measurement technology is the key to guarantee product quality and productivity. Traditional contact measurement methods often have drawbacks such as low efficiency and easy to damage the workpiece, while the emergence of spectral confocal sensors has revolutionized industrial automation.

Spectral Confocal Sensor Detection Characteristics

1.Non-contact measurement: no need to contact the object to be measured, avoiding damage to the precision workpiece, especially suitable for soft, easy to deform the measurement of objects.

2.High precision: sub-micron or even nanometer resolution can be realized to meet the demand for high-precision measurement.

3. High speed measurement: thousands of measurements per second, to meet the needs of online real-time inspection.

4. Strong adaptability: It can measure a variety of materials, colors and surface characteristics, including highly reflective, transparent, multi-layer materials, and so on.

Spectral Confocal Sensors in Industrial Automation

-

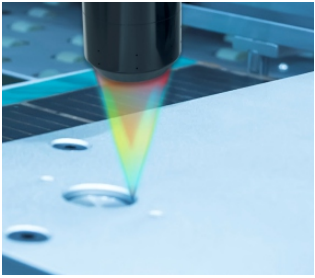

Surface Defect Detection: It can accurately identify scratches, pits, cracks and other defects on the surface of the product, which is widely used in the quality inspection of chips, displays, precision parts and other products.

-

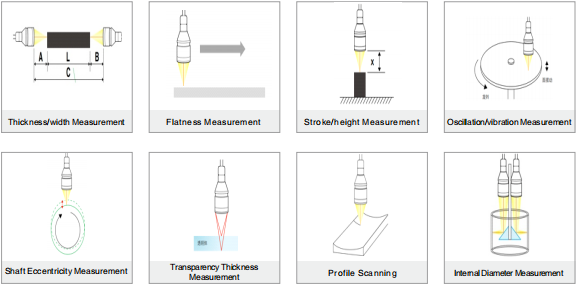

Dimension Measurement: It can quickly and accurately measure the length, width, height, thickness and other dimensional parameters of the parts, which is widely used in the fields of machining and electronic manufacturing.

-

Morphology Measurement: Reconstruct the three-dimensional morphology of the object surface, used to assess the surface roughness, flatness, contour, etc., used in mold processing, additive manufacturing and other fields.

-

Displacement Measurement: Real-time monitoring of object displacement changes, used in robot positioning, vibration analysis, thickness control and other scenarios.

Application Cases

-

Mobile Phone Screen Inspection: Utilizing spectral confocal sensors to inspect the surface defects, thickness and curvature of the cell phone screen in an all-round way to ensure the quality of the screen.

-

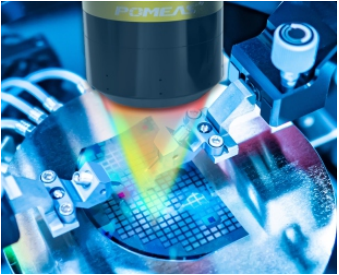

Chip Package Inspection: Measure the surface morphology and solder joint height of the chip package with high precision to ensure the performance and reliability of the chip.

-

Automotive parts inspection: automated inspection of engine parts, gears, bearings and other key components of the dimensional accuracy, surface roughness, etc., to improve production efficiency and product quality.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION