Zoom lens solutions: Dust screen impurity detection for electronic equipment

Programmatic background

With the development trend of intelligent and thin and light electronic devices, speakers, as an important acoustic component, the quality of the process of its dust mesh directly affects the sound quality and service life of the device. However, in the production process of dust mesh, burrs, foreign objects and other impurities will inevitably be generated, and the presence of these impurities will block the mesh holes, affecting the sound transmission, and even lead to damage to the loudspeaker. Therefore, it is crucial to conduct strict impurity detection on the dust screen before leaving the factory.

The traditional impurity detection of dust screen mainly relies on manual visual inspection, and this method has drawbacks, such as: low efficiency, high leakage rate, and the detection results are affected by the experience of the personnel, state and other factors, which makes it difficult to ensure consistency.

Solution Provider

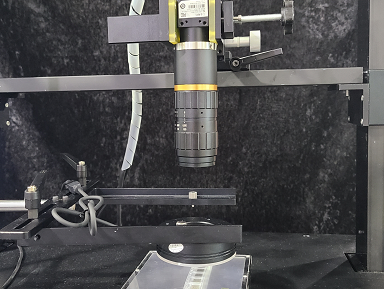

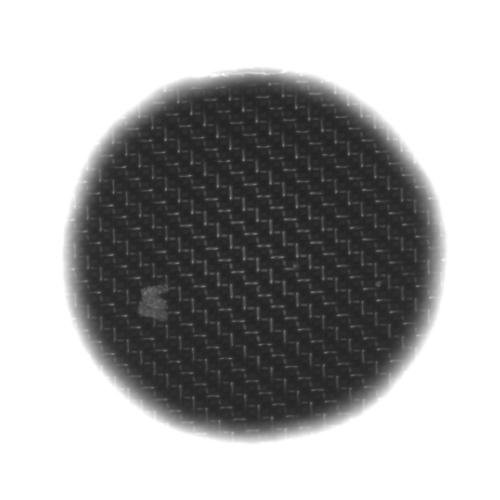

In order to solve the limitations of traditional inspection methods, we built a zoom lens solution for detecting impurities in the dust mesh of loudspeakers for electronic devices. The solution utilizes a high-resolution industrial camera with a POMEAS 6.5X continuous zoom lens to achieve fully automatic, high-precision detection of dust mesh.

Program Advantages

-

Highly accurate inspection: POMEAS 6.5X continuous zoom lens can realize 6.5X optical zoom, which can clearly show the details of the surface of the dust screen and effectively identify the tiny impurities.

-

High Efficiency Inspection: The automated inspection system can quickly complete the scanning of a large area of dust screen, which significantly improves the inspection efficiency.

-

Highly stable detection: The system adopts advanced image processing algorithms to automatically identify and classify impurities, ensuring the accuracy and consistency of the detection results.

-

Traceable data: The system can record the inspection data and generate reports, which is convenient for quality tracing and analysis.

Program Examples

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION