FA lenses for deformation detection of thin-walled machined parts

In modern manufacturing, thin-walled machined parts are widely used in aerospace, automobile manufacturing, electronic equipment and many other fields due to their lightweight, material-saving advantages. However, due to its own structural characteristics, thin-walled machined parts are very susceptible to deformation during the machining process, which has a serious impact on the precision and quality of the product. Therefore, accurate and efficient deformation detection technology has become the key to ensure the quality of thin-walled machined parts.FA lenses, as an important tool in the field of industrial vision inspection, play an important role in the deformation detection of thin-walled machined parts, but also face a series of challenges.

Importance of deformation detection for thin-walled machined parts

The thickness of thin-walled machined parts is usually thin, generally at the millimeter or even sub-millimeter level. In the machining process, such as cutting, stamping, welding and other processes, may be due to uneven force, thermal stress and other factors lead to deformation of the workpiece. For example:

① In the manufacture of aircraft engines, the small deformation of thin-walled blades may affect the performance and safety of the engine;

② In the manufacture of automotive parts, the deformation of thin-walled structural components will affect the assembly accuracy and driving stability of the vehicle. Accurately detect the deformation of thin-walled machined parts, can adjust the processing technology in time to avoid the generation of scrap, reduce production costs and improve production efficiency.

Limitations of traditional detection methods

Traditional deformation detection methods for thin-walled machined parts mainly include contact measurement and simple non-contact measurement. Contact measurement, such as the use of calipers, micrometers and other tools, although you can get a high degree of measurement accuracy, but the detection speed is slow, inefficient, and easy to damage the surface of thin-walled machined parts, is not suitable for large-scale production inspection. Simple non-contact measurement, such as laser rangefinders, can only obtain a limited number of points of data, it is difficult to comprehensively reflect the overall deformation of the workpiece, for the detection of complex shapes of thin-walled machined parts is not effective.

Examples of FA lenses used in deformation detection of thin-walled machined parts

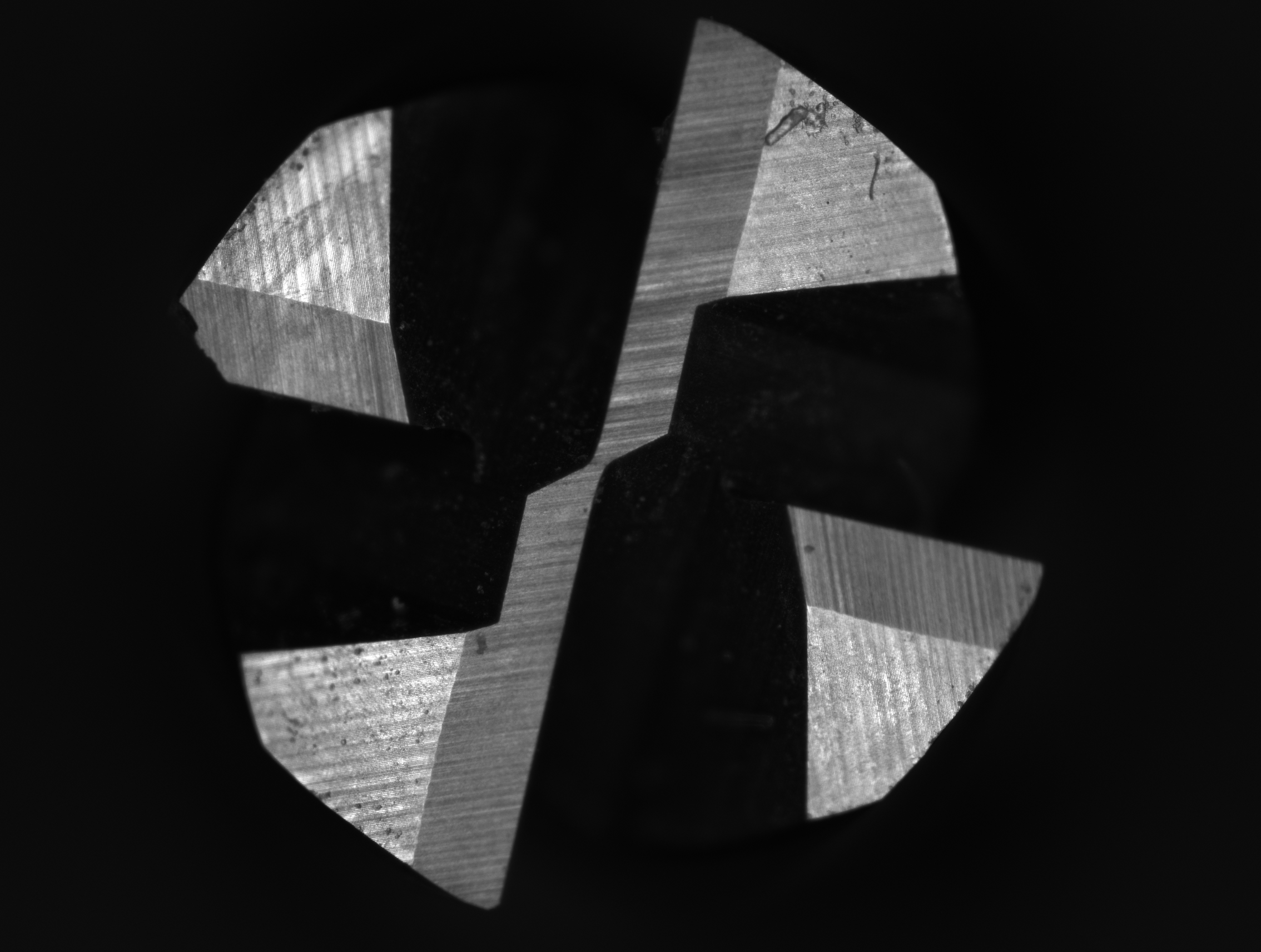

1、High-precision imaging

FA lenses provide high-resolution and high-definition imaging capabilities to clearly capture the surface details of thin-walled machined parts. In practice, by using FA lenses in conjunction with industrial cameras, thin-walled parts can be photographed from all sides. For example, in the thin-walled machined parts inspection of electronic equipment shell, FA lenses can clearly present the shell surface of the small deformation, such as depressions, bumps, etc., for the subsequent data analysis provides an accurate image base. Detectors can be based on these images to accurately measure the location, size and degree of deformation.

2、3D modeling and analysis

With the help of advanced image processing software and algorithms, the images collected by the FA lens can be used to build 3D models of thin-walled machined parts. Through the analysis of the 3D model, the overall deformation of the workpiece can be visualized. Taking the inspection of automotive aluminum alloy thin-walled wheel hub as an example, the multi-view image acquired by the FA lens is used to generate a 3D model of the wheel hub. Comparing the actual model with the standard model, it can quickly and accurately identify the deformation areas of the wheel hub generated during processing, such as the ellipticity deviation of the rim, the distortion of the spokes, etc., which provides comprehensive data support for the quality assessment of the wheel hub.

3、Real-time on-line inspection

On the production line, FA lens can realize real-time on-line inspection of thin-walled machined parts. By setting the appropriate detection station, the FA lens can be processed or just finished processing of thin-walled parts for instant detection. Once the deformation is detected to be out of the permissible range, the system will immediately send out an alarm to notify the operator to adjust the processing parameters in time or to handle the workpiece. This real-time online inspection greatly improves the quality control level of the production process, reduces the generation of scrap and improves production efficiency.

FA Lens Application Challenges and Strategies

1. Complex Light Environment Adaptability

In the actual production workshop, the light environment is complex and changeable, and there are many interfering factors such as strong light, backlight, reflected light, etc., which have a greater impact on the imaging quality of FA lenses. To meet this challenge, Promise has developed FA lenses with automatic dimming function, which can automatically adjust the aperture, exposure time and other parameters according to changes in ambient light to ensure that clear images can be obtained under different light conditions. Meanwhile, special optical coating technology is adopted to reduce light reflection and refraction and improve the anti-interference ability of the lens.

2. Improvement of micro-deformation detection accuracy

The deformation of thin-walled machined parts is often very small, which requires very high detection accuracy. In order to further improve the accuracy of micro-deformation detection, Bumis continuously optimizes the optical design of FA lenses to improve the resolution and image quality of the lenses. At the same time, the combination of advanced image processing algorithms, such as sub-pixel positioning algorithms, enables more accurate measurements at the image level, and improves the accuracy of detecting small deformations down to the micron level.

3. Adaptability to different machining processes

Different thin-wall machining processes, such as cutting, stamping, injection molding, etc., lead to different types and characteristics of deformation in the workpiece. By deeply studying the influence of various machining processes on the deformation of thin-walled parts, P&M has developed corresponding inspection programs and algorithms for different processes. For example, for the deformation caused by the stamping process, the FA lens is used to focus on detecting the edges and rounded areas of the workpiece; for the deformation caused by the injection molding process, attention is paid to the uniformity of the workpiece's wall thickness and surface flatness. This customized solution improves the accuracy and effectiveness of FA lenses in detecting deformation of thin-walled parts under different processing techniques.

FA lenses have shown great potential in the deformation detection of thin-walled machined parts, providing the manufacturing industry with an efficient and accurate means of quality inspection. Despite the many challenges, POMEAS will continue to improve the performance and application of FA lenses through continuous technological innovation and optimization to help the manufacturing industry achieve higher quality development.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com