A New Choice for Measurement: Inline Projection Measurement Solutions

Traditional image measurement methods often require complex equipment and cumbersome operating procedures, making it difficult to meet the dual demands of modern industry for efficiency and accuracy. The emergence of online projection measurement solutions has brought a new choice to the image measurement field.

What is in-line projection measurement?

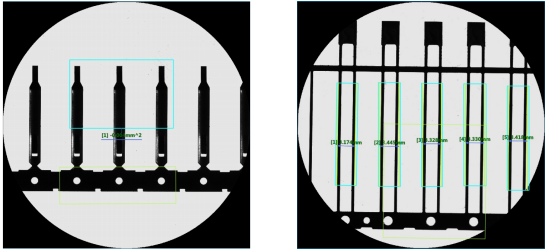

On-line projection measurement is a non-contact measurement method based on optical projection and image processing techniques. It calculates the dimensional information of the object by projecting a specific pattern onto the surface of the object to be measured and using a camera to capture the deformed pattern, combined with an algorithm to analyze and calculate the dimensional information of the object.

Advantages of an online projection measurement solution:

-

Efficient and Convenient: Quickly acquire 3D data without touching the object, greatly improving the measurement efficiency.

-

High Accuracy: Using advanced image processing algorithms, it can realize micron or even nanometer measurement accuracy.

-

Adaptable: It can measure objects of various materials, shapes and sizes, with a wide range of applications.

-

High degree of automation: can be integrated with the production line to realize automated online measurement, reducing manual intervention.

-

Data visualization: Measurement results can be displayed and analyzed in real time, which is convenient for users to carry out quality control and process optimization.

Application areas for online projection measurement solutions:

-

Electronic manufacturing: PCB board inspection, chip size measurement, component welding quality inspection, etc.

-

Mechanical processing: parts size measurement, shape and location tolerance inspection, surface defects detection.

-

Automobile manufacturing: body size measurement, parts assembly inspection, surface quality inspection, etc.

-

Aerospace: aircraft parts inspection, engine blade measurement, composite material inspection, etc.

-

Medical devices: prosthesis sizing, surgical navigation, orthodontics, etc.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION