In many fields such as precision manufacturing, scientific research and quality inspection, the need for accurate measurement of object dimensions is extremely urgent. As a kind of efficient and accurate measuring tool, image size measuring instrument has emerged and developed a rich variety of types. In the face of a wide range of products, how to select the most suitable for their own one, has become the focus of attention of many users.

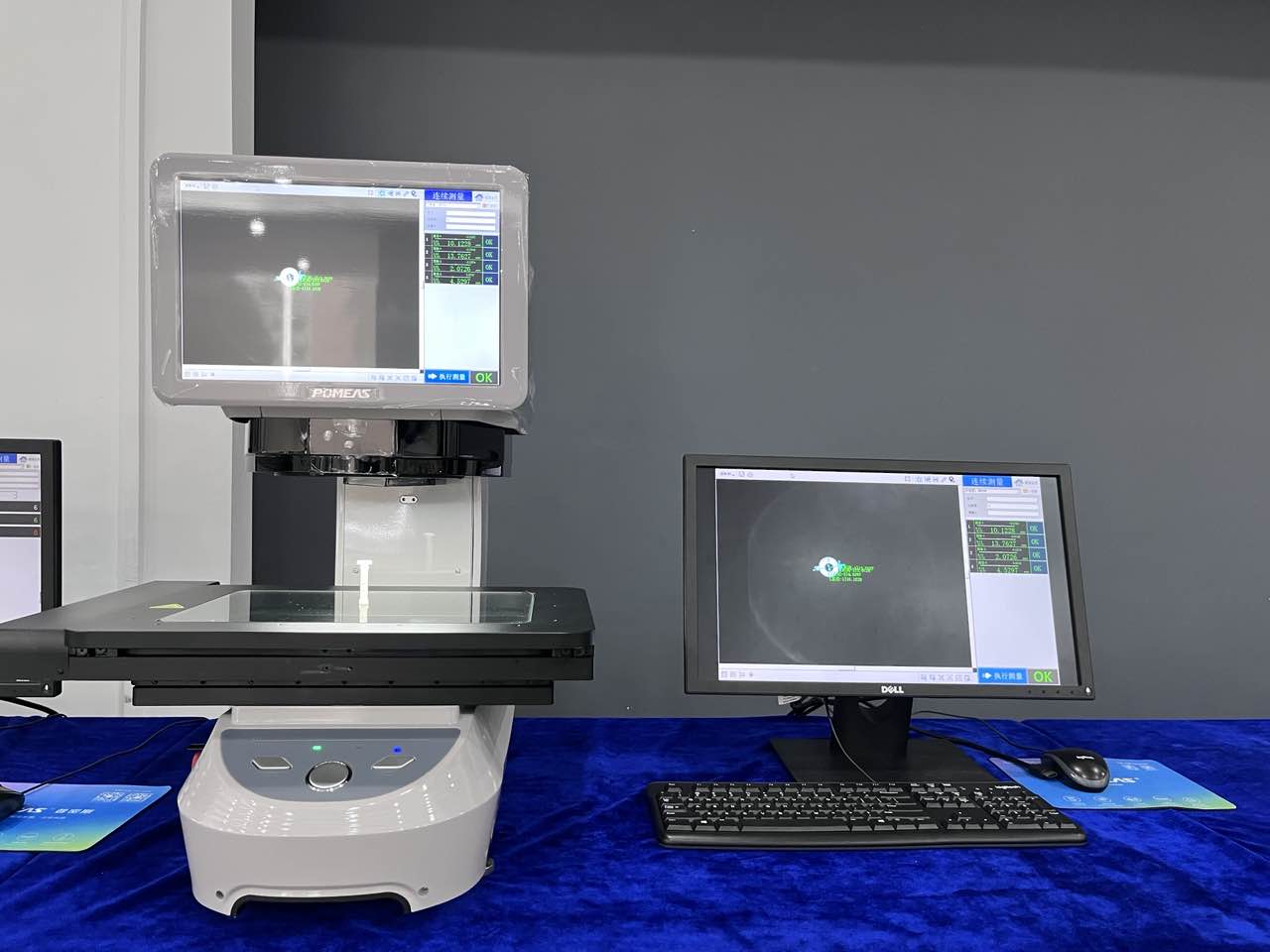

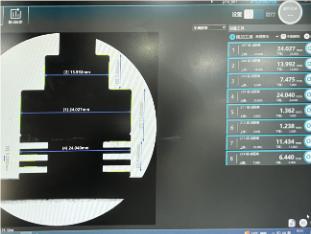

Optical Microscope Type Image Dimension Measuring Instrument

Optical microscope type image size measuring instrument, is the traditional optical microscope and modern image measurement technology combined product. It is mainly with the help of optical lens on the target object to magnify the image, and then through the image sensor image acquisition, and the use of professional measurement software on the image of the object size measurement and analysis.

1、Working Principle

From the microscopic level, light passing through the specimen is magnified through multiple stages of objective and eyepieces to form a clear magnified image on the image sensor. Based on the pixel information of the image, the measurement software accurately calculates the length, width, diameter, angle and other parameters of the object based on the proportional relationship between the pre-calibrated pixels and the actual size. For example, in the dimensional measurement of tiny electronic components, the instrument is able to clearly present the microstructure of the components, and the software measures key parameters such as the width of the pins and the size of the chip.

2、Applicable Scenarios

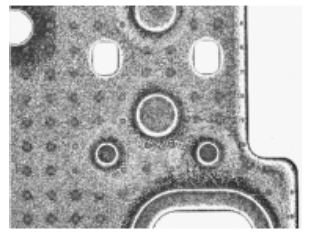

① Microelectronics industry: In the process of chip manufacturing, the control of dimensional parameters such as photolithographic precision and circuit line width of the chip is crucial. Optical microscope-type image size measuring instrument can meet the demand for nano-scale size measurement to ensure the high precision of chip manufacturing.

② Biomedical research: in the study of cells, microorganisms and other microscopic biological samples, the measurement of cell size, microbial morphology and size, etc., helps to gain a deeper understanding of biological growth, development and disease mechanisms.

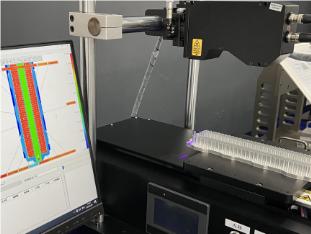

Laser Scanning Image Dimension Gauge

Laser Scanning Image Dimension Measuring Instrument is a device that uses laser technology to acquire three-dimensional information about the surface of an object and realises dimensional measurement through image reconstruction and measurement algorithms.

1、Working Principle

A laser beam is emitted to scan the surface of an object in a specific scanning pattern. The laser beam is reflected on the surface of the object and the reflected light is received by a detector. Based on the time difference between the emission and reception of the laser light (time-of-flight method), or the phase change of the laser beam (phase method), the distance of the laser beam from each point on the surface of the object can be accurately calculated. By collecting and processing a large amount of distance data, a three-dimensional model of the object's surface is constructed, and the dimensional parameters of the object are then measured. For example, in the dimensional inspection of automotive parts, laser scanning can quickly obtain three-dimensional data of the complex surface of the parts.

2、Applicable Scenarios

① Automobile manufacturing and aerospace field: For the size inspection and quality control of large and complex parts such as automobile engine block and aircraft wings, laser scanning image size measuring instrument can quickly and comprehensively obtain the size information of the parts and detect the possible manufacturing defects.

② Heritage protection and digital reconstruction: in the protection and research of cultural relics, laser scanning can obtain accurate three-dimensional dimensional data of cultural relics for digital archiving of cultural relics, restoration programme development and virtual display.

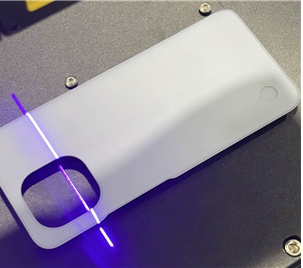

Machine Vision Type Image Dimension Measuring Instrument

Machine vision type image size measuring instrument is a device based on computer vision technology to achieve size measurement through the analysis and processing of images. It integrates many advanced technologies such as image processing, pattern recognition, artificial intelligence and so on.

1、Working Principle

An industrial camera is used to capture the image of the object and transmit the image to the computer. The image processing software in the computer carries out a series of pre-processing operations such as greyscaling, filtering, edge detection, etc. to extract the edge contour of the object. Then, the features of the object are recognised and matched by the pattern recognition algorithm to determine the position and attitude of the object. Finally, the dimensional parameters of the object are calculated according to the pre-set measurement algorithm and calibration parameters.

2、Applicable Scenarios

① Industrial automated production line: widely used in automated production lines in electronics, automotive, machinery manufacturing and other industries, real-time online size detection and quality control of products to ensure product quality consistency and stability.

② Logistics and packaging industry: in the logistics sorting process, used to measure the size of the goods, in order to reasonably arrange the storage space and transport vehicles; in the packaging industry, to detect whether the size of packaging materials in line with the requirements of the product, to ensure the integrity of the packaging and aesthetics.

Q: How do I choose the right image size measurement device for me?

Choosing the right image size measuring instrument, you need to first define the measurement needs, such as the accuracy requirements are micron-level or higher, and the measurement range can cover the size of the object being measured; then consider the functional characteristics, such as the camera resolution, frame rate, and whether the software has a practical function of the image analysis, automatic identification, etc.; the ease of operation is also very critical, user-friendly interface, a high degree of automation can enhance the efficiency; and at the same time to pay attention to the brand's reputation At the same time, we should pay attention to the brand reputation and after-sales service, the well-known brand product quality is more reliable, after-sales can solve the problem in a timely manner; finally, combined with the budget, in order to meet the requirements of the basis of the selection of cost-effective products.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com