In-line image measuring instrument makes quality inspection easier

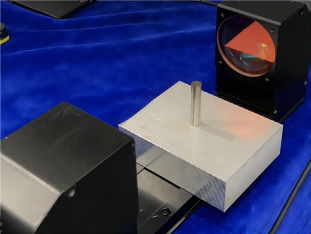

In modern manufacturing, quality inspection is a key aspect to ensure product competitiveness. Especially in the field of plastic parts manufacturing, dimensional accuracy and surface quality directly affect the performance and appearance of products. Traditional measurement methods are often inefficient and error-prone, and the emergence of in-line image measuring instruments has completely changed the situation. With its high accuracy, high efficiency and non-contact measurement, in-line image measuring instrument makes quality inspection easier and more reliable. Today, we will take the measurement of plastic parts as an example, and bring you an in-depth understanding of how online image measuring instrument can help enterprises to achieve accurate measurement.

The Challenge of Measuring Plastic Parts

Plastic parts are widely used in automotive, electronics, home appliances and other industries, which have complex shapes, diverse sizes, and high requirements for accuracy. Traditional measurement methods, such as calipers and micrometers, are not only time-consuming and labour-intensive, but also difficult to cope with the measurement needs of complex shapes. In addition, the characteristics of plastic parts, such as easy deformation and surface reflection, also bring considerable challenges to the measurement.

Advantages of in-line image measurement

1. Non-Contact Measurement: The In-Line Image Measuring Instrument adopts non-contact measurement to avoid physical contact with the surface of plastic parts, thus preventing deformation or damage caused by measurement.

2. High accuracy and efficiency: With high-resolution optics and intelligent algorithms, the in-line image measuring instrument is capable of achieving micron-level accuracy, while significantly improving inspection efficiency to meet the needs of high-volume production.

3. Complex Shape Measurement: Whether it's a curved surface, a hole, or an irregular edge, in-line image measurement is easy to handle, ensuring accurate measurement of complex shapes.

4. Automated Inspection: The in-line image measuring instrument can be seamlessly integrated with the production line to achieve fully automated inspection, reducing human intervention and human error.

5. Data management: Measurement results can be saved and reports generated in real time, facilitating quality traceability and analysis and helping companies optimise their production processes.

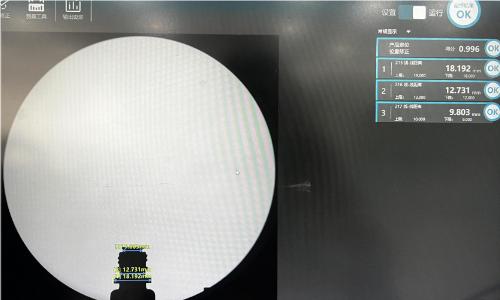

Example of in-line image measurement results on plastic parts:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION