Variable navigation, 4k variable detection program, each based on what “out of the circle”?

In the field of industrial vision inspection, POMEAS's variable navigation solutions and variable inspection solutions stand out and become the choice of many companies. So, what exactly makes them “out of the loop” in the fierce market competition? Today, we will find out.

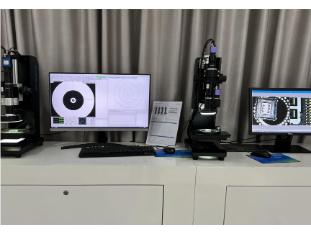

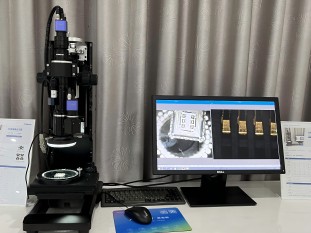

Variable navigation solutions: “multi-faceted” for visual inspection

The variable navigation solution is mainly used in the field of visual inspection, and its biggest highlight is equipped with a dual camera system. This unique design gives it a powerful observation capability. On the one hand, it can easily observe a wide range of viewing angles, just like having a pair of “wide-angle eyes”, and can quickly capture the overall contour and positional information of the target object, laying the foundation for subsequent accurate inspection. On the other hand, when it is necessary to pay attention to the details, the dual cameras can accurately observe and zoom in on the product details, as if switching to the “macro mode”, not sparing any subtleties.

This ability to observe a wide range and accurately control the details makes the variable navigation solution play an important role in many industries such as electronics manufacturing and automotive parts inspection. For example, in electronic chip inspection, it can quickly scan the whole chip to find defects on the chip surface, short circuit of the line and other problems, and at the same time, it can zoom in on the tiny soldering joints to detect whether their soldering quality is up to standard or not.

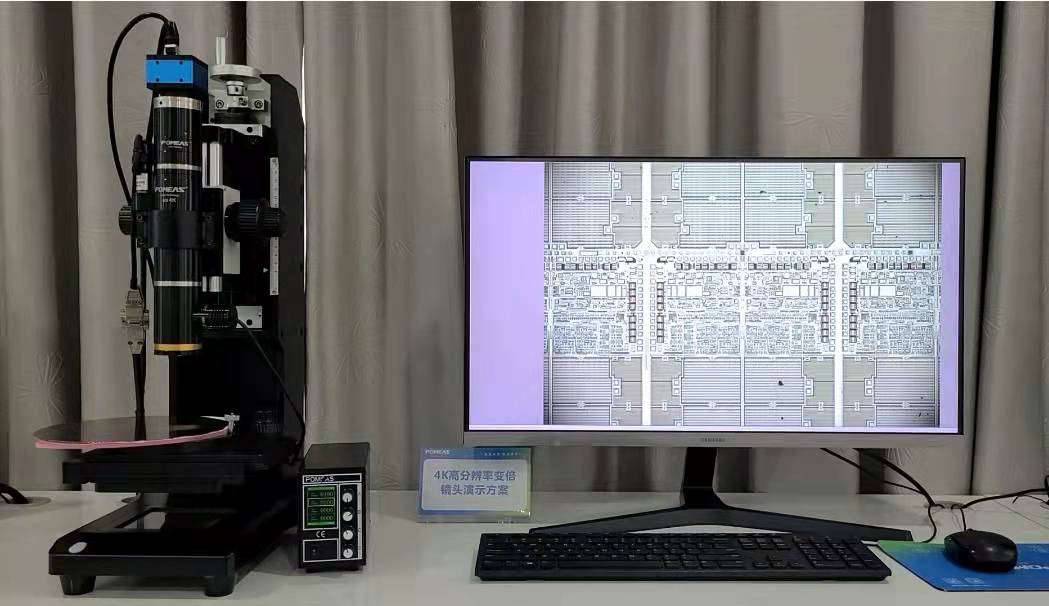

4K zoom inspection solution: the “master of precision” for product size measurement

The Variable Inspection Solution is unique with its 4K HD lens and automatic magnification adjustment, which provides extremely clear images, making every detail of the inspection process visible. The auto-magnification function is an added benefit, as it automatically matches the most suitable magnification to the inspection needs without manual adjustment, greatly improving the inspection efficiency.

With these advantages, the zoom inspection solution excels in product dimensional measurement. Whether it is the dimensional inspection of precision mechanical parts or the dimensional measurement of cell phone screens, it can accurately give the measurement results with minimal error. This is undoubtedly a great blessing for the manufacturing industry, which requires very high dimensional accuracy, and can effectively ensure product quality and reduce the defective rate.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION