3D Contouring, Defect Detection All in One, How Good is the Line Laser Sensor Solution?

In the field of industrial inspection and smart manufacturing, the requirements for product accuracy and quality inspection are becoming increasingly stringent. POMEAS' line laser sensor solution stands out from other inspection technologies with its excellent performance, easily realizing 3D contour mapping and defect detection, and providing strong support for manufacturing in various industries. Here, let's take a deeper look at how good it really is.

How 3D Inspection Works

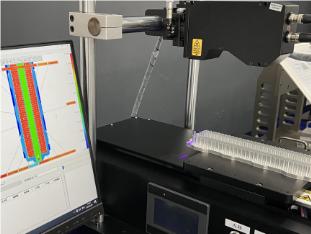

The operating principle of the line laser sensor solution is based on triangulation. When the laser beam emitted by the line laser hits the product surface, a bright line is formed. Due to the undulating surface of the product, this bright line is reflected at different angles at different locations. The sensor receives the reflected light and utilizes triangulation to accurately calculate the 3D coordinates of each point to quickly construct a 3D profile of the product in software. This process is like an all-around “digital scan” for the product, which presents every detail of the product clearly.

Widely used to solve industry pain points

( i ) 3D backwriting, help product innovation and design

In the process of product development, 3D reverse engineering is an important technical application. The line laser sensor solution can quickly obtain 3D data of existing products, and through reverse engineering technology, transform these data into editable CAD models. Designers can base their innovative designs on these models to optimize product structures, shorten development cycles and reduce development costs. Whether it is complex mechanical parts or delicate electronic product shells, the line laser sensor solution can accurately complete the 3D reverse writing task, injecting new vitality into product innovation.

(ii) Accurate defect detection to ensure product quality

Product defect detection is a key part of the production process. The line laser sensor program can scan the product surface and quickly detect defects such as scratches, holes, deformations and other types of defects. By comparing with a preset standard model, the system can accurately calculate the location, size and shape of the defects, providing accurate data support for quality control during the production process. In the automotive parts manufacturing, aerospace and other industries with extremely high product quality requirements, the application of line laser sensor program greatly improves the product qualification rate and reduces the losses caused by defective products.

Technical Advantages

(i) High Accuracy Detection

The POMEAS line laser sensor solution offers extremely high inspection accuracy, capable of distinguishing differences in detail down to the micron level. This makes it particularly good at inspecting tiny parts or products that require high precision. Whether it's measuring the pin spacing of a precision electronic component or inspecting the surface flatness of an optical lens, the task can be accomplished with precision.

(ii) Fast inspection speed

In industrial production, time is efficiency. Line laser sensor program with its fast scanning speed, can be completed in a short period of time to the full inspection of the product. High-speed data acquisition and processing capabilities ensure that products on the production line can be detected in a timely manner, which improves production efficiency and meets the needs of mass production.

( iii) Stable and Reliable Performance

POMEAS has always been committed to technology development and product quality improvement, line laser sensor program adopts advanced optical and electronic components, with stable and reliable performance. In complex industrial environments, it can resist external interference and ensure the accuracy and consistency of detection results. At the same time, the perfect after-sales service system, to provide customers with a full range of technical support and protection, so that customers have no worries.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com