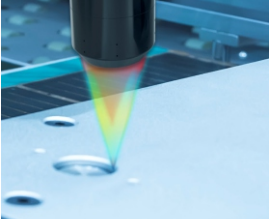

Spectral Confocal Sensor Principle

Spectral confocal sensors are an optical detection method based on axial chromatic aberration and color coding techniques. The basic principle is that the complex color light emitted from the emitting end of the sensor is dispersed into spectra of consecutive wavelengths, and these spectra are accurately mapped onto the DUT through color coding. When this light is reflected by the object, the sensor measures the wavelength of the reflected light to establish a correspondence between the distance of the sensor and the surface of the object, thus obtaining information about the position of the object.

Spectral Confocal Sensors in the 3C Industry

1, cell phone panel glass detection: spectral confocal sensor can be used for cell phone panel glass contour and edge detection, to ensure the accuracy and quality of the panel glass.

2, circuit defect detection: in the semiconductor manufacturing process, the sensor can accurately detect defects in the circuit, such as cracks, breaks, etc., thus improving product reliability and stability.

3, precision structural components size detection: sensors can be used to measure the size of precision structural components, such as cell phone camera module, fingerprint identification module, etc., to ensure the accuracy and compatibility of these components.

4, chip package appearance detection: in the process of chip packaging, the sensor can detect the appearance quality of the package body, such as bubbles, scratches, etc., to ensure the integrity of the chip package.

Application Scenarios

1、Semiconductor industry: sensors can be used for wafer inspection, chip bead coplanarity detection, etc., to ensure the quality and performance of semiconductor products.

2、Optical components manufacturing: in the manufacturing process of optical components such as lenses, prisms, etc., the sensor can be used to measure the thickness of the component, the surface shape and other parameters, to ensure the stability of optical performance.

3、Precision machining: sensors can be used to measure the size, shape and other parameters of mechanical components to ensure processing accuracy and assembly quality.

4、Automotive industry: Sensors can be used for displacement and vibration measurement of engine, suspension, tires and other components, real-time monitoring of their mechanical performance parameters, in order to improve their operational efficiency and safety.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION