Application of Image Measuring Instrument in PLC Repeater Board Measurement

With the rapid development of modern industrial automation, PLC (Programmable Logic Controller) as the core equipment of industrial automation system, its performance and stability are crucial. As an important part of PLC, the relay board assumes the key functions of signal transmission, amplification and conversion. However, due to the close layout and complex working environment of the components on the relay board, the accuracy and efficiency of its measurement are highly demanded.

PLC Relay Board Measurement Background

The components on the PLC relay board are of various types and sizes, and are connected and laid out very closely to each other. Traditional measurement methods, such as the use of vernier calipers, micrometers and other tools, are not only cumbersome and inefficient, but also susceptible to the influence of human factors, resulting in insufficient measurement accuracy. In addition, as the degree of industrial automation increases, the demand for PLC relay board measurement is also increasing, and the traditional methods can no longer meet the requirements of efficient and accurate measurement.

Advantages of Image Measuring Instruments

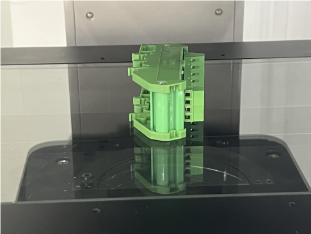

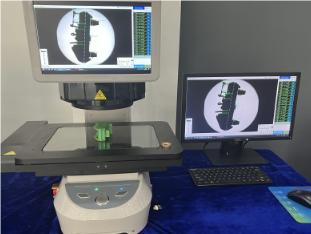

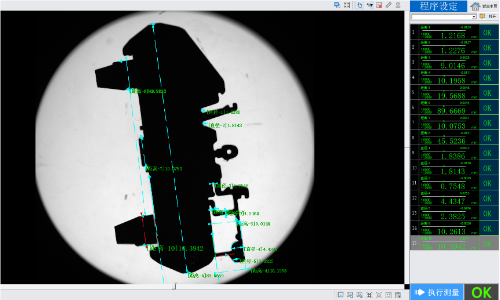

The POMEAS Image Dimension Gauge provides an efficient and accurate solution to the challenges of PLC relay board measurement. Adopting advanced image processing technology, the gauge can automatically recognize and measure multiple dimensional elements with just one-button operation, which greatly improves inspection efficiency. Meanwhile, due to its non-contact measurement method, it avoids the errors and damages that may be caused by traditional measurement tools, ensuring the accuracy of the measurement.

Application of Image Measuring Instrument in PLC Repeater Board Measurement

1. Efficient Measurement: POMEAS Image Dimension Measuring Instrument is able to quickly identify and measure multiple dimensional elements on PLC relay boards, which greatly shortens the measurement time and improves productivity.

2. Highly accurate measurement: Adopting advanced image processing algorithms, it can accurately recognize the contours and dimensions of the elements on the repeater board to ensure the accuracy of the measurement results.

3. Non-contact measurement: Avoiding the physical damage and errors that may be caused by traditional measuring tools, protecting the components on the relay board from damage.

4. Easy to operate: One-button operation interface is simple and intuitive, reducing operation difficulty and improving measurement efficiency.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION