How accurately do online projected image gauges measure key dimensions?

As a common hardware accessory in modern manufacturing, the dimensional accuracy of keys directly affects the performance of locks and the user experience. So how to quickly and accurately measure each key dimension of a key? Online projected image measuring instrument gives the perfect answer.

Key Size Measurement Requirements

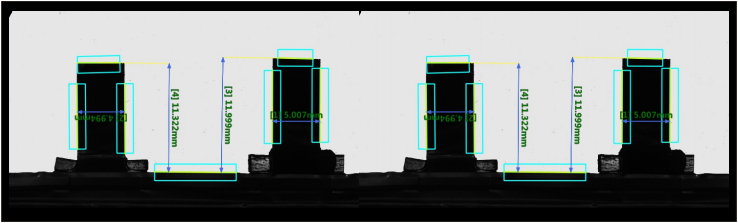

The dimensional measurement of a key involves a number of key parameters, including length, width, thickness, tooth height, tooth spacing, shoulder dimensions, and slot width and depth. Together, these parameters determine the functionality of the key and its fit to the lock cylinder. While traditional manual measurements are not only inefficient but also prone to errors, the in-line image measuring instrument realises non-contact, fast and accurate measurements by means of a high-precision camera and advanced image processing technology.

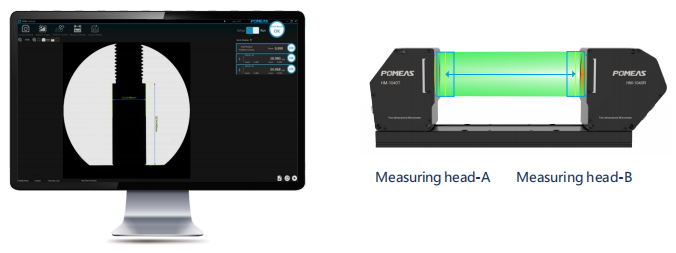

Principle of operation of the in-line image measuring instrument

The in-line image measuring instrument captures an image of the key with a high-resolution camera and analyses the image using intelligent algorithms to automatically extract the individual dimensional parameters of the key. Whether it is the overall length of the key, the height of the teeth, or the complex width and depth of the slot, the gauge measures it in seconds and presents the results in digital form.

Advantages of in-line image measurement

1、High precision: the measurement accuracy can reach micron level, ensuring the absolute accuracy of the key size.

2、High efficiency: automated measurement process, significantly shorten the measurement time and improve production efficiency.

3、Multi-functionality: not only for keys, but also can be widely used in hardware, plastic, 3C, medical and other industries for complex parts measurement.

4、Data management: Measurement results can be automatically recorded and reports generated for easy quality traceability and analysis.

Application Scenarios

In-line image measuring machines are not only suitable for key manufacturing and inspection, but also show strong application potential in areas such as hardware processing parts, plastic manufacturing parts, the 3C industry and medical parts. For example, in the 3C industry, the dimensional inspection of miniature parts requires extremely high precision; in the medical industry, the contour measurement of complex parts also places very high demands on the equipment. With its high precision and versatility, the in-line image measuring instrument can easily meet these challenges and become an indispensable measuring tool in modern manufacturing.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION