How to choose between different types of online image measuring instruments?

In the field of industrial production and manufacturing, accurate dimensional measurement is crucial to ensure product quality. As a kind of efficient and accurate measuring equipment, in-line image measuring instrument is widely used in plastic manufacturing parts, hardware processing parts, 3C industry, medical parts and many other fields. POMEAS has three types of in-line image measuring machines: HM-1040, HM-1065 and HM-1120.

Importance of measurement range and accuracy

Measuring range and accuracy are two key factors to focus on when selecting an online image measuring instrument. Measuring range determines the size of the object that the instrument can measure, while accuracy directly affects the accuracy of the measurement results. Different production scenarios and products have different requirements for measuring range and accuracy.

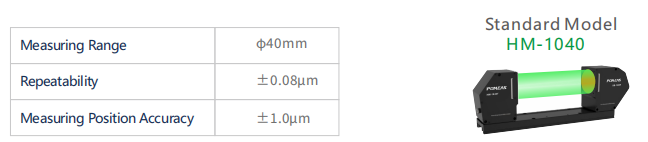

HM-1040 Standard Model

-

Parameters: Measuring range up to 40 mm diameter, accuracy up to 1.0 μm.

-

Applicable Scenario: It is suitable for measuring small precision parts with very high accuracy requirements, such as in the 3C industry, like the tiny parts in the camera module of mobile phones, chip pins, etc., which are small in size and demanding in accuracy, HM-1040 can accurately measure their dimensions to ensure that the products comply with the strict quality standards; in the field of medical parts, some small medical equipment accessories, such as insulin pens, needles, micro sensor components, etc., also need this high precision measuring instrument to ensure production quality. In the field of medical parts, some small medical device accessories, such as insulin pens, needles, micro-sensor components, etc., also need this high-precision measuring instrument to ensure the quality of production.

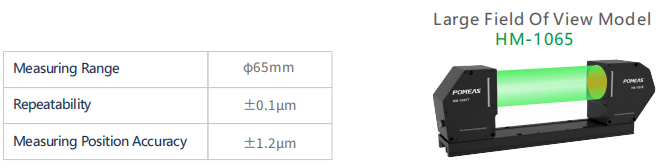

HM-1065 Large Field of View Model

-

Parameters: Measuring range up to 65 mm diameter, accuracy up to 1.2 μm.

-

Applicable Scenario: Suitable for the measurement of medium-sized parts, in the hardware processing parts, some common nuts, bolts, small mechanical parts, etc., the size of which is mostly in this range, HM-1065 can meet the demand for the measurement range, but also to detect the size deviation and surface defects of the parts with high precision; in the plastic manufacturing parts, such as some small plastic gears, plastic shells, etc., the model can also play an excellent measurement performance to help quality control in the production process. In the plastic manufacturing parts, such as some small plastic gears, plastic shells, etc., this model can also play an excellent measuring performance, help the quality control in the production process.

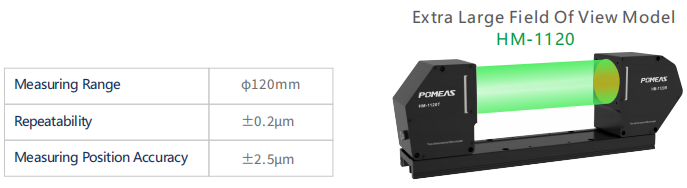

HM-1120 Ultra Large View Model

-

Parameters: Measuring range up to 120 mm diameter, accuracy up to 2.5 μm.

-

Applicable scenarios: mainly for large parts or scenarios that require large area measurement. In the 3C industry, for some larger size tablet computer screen, laptop shell, etc., it can achieve one-time complete measurement; in the field of hardware processing, large mechanical parts, moulds, etc., HM-1120's large field of view can quickly obtain the overall dimensional information, although the accuracy of the first two models is slightly lower, but for the measurement of such large parts has been sufficient to meet the production requirements.

When choosing an online image measuring instrument, it is important to define the range of product sizes you need to measure and the requirements for accuracy. If it is a small precision parts, the accuracy requirements are very high, then the HM-1040 standard model is the choice; if the measurement of medium-sized parts, the field of view and accuracy have a certain balance of needs, HM-1065 large field of view model will be more appropriate; and for large parts or large area measurement tasks, HM-1120 ultra-large field of view model will be able to play its unique advantages. Only by choosing the right model according to the actual needs, can we give full play to the role of on-line image measuring instrument, improve production efficiency and product quality.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com