Differences between projection measurement lenses and normal projection lenses

In the projection technology is widely used nowadays, from the cozy viewing in home theater, to the precision measurement in industrial production, the projection lens as a core component, its performance directly affects the projection effect. The projection measurement lens and the ordinary projection lens, although both serve in the projection scene, but they have significant differences in many aspects.

Optical Structure

( A )Projection Measurement Lens

The optical structure of projection measuring lenses is designed to be extremely complex in order to meet the needs of high-precision measurement. It usually employs a combination of multiple high-precision lenses that are specially ground and coated to minimize aberration and chromatic aberration as light travels between the lenses. For example, to correct for spherical aberration, aspherical lenses are used, whose unique curved shape allows light to converge more evenly on the imaging surface. Meanwhile, to improve measurement accuracy, the spacing and position of the lenses inside the lens can be precisely adjusted to suit different measurement objects and measurement accuracy requirements.

( B )Normal Projection Lens

The optical structure of ordinary projection lenses is relatively simple, mainly focusing on realizing clear projection and magnification of images. It generally uses a more conventional lens combination, lens grinding and coating process to meet the basic needs of projection, the correction of aberration and chromatic aberration requirements are relatively low. The lens spacing and position of ordinary projection lenses are fixed at the time of production and cannot be adjusted accurately, aiming to achieve stable projection of images at a lower cost.

Imaging Quality

( A ) Projection measuring lenses

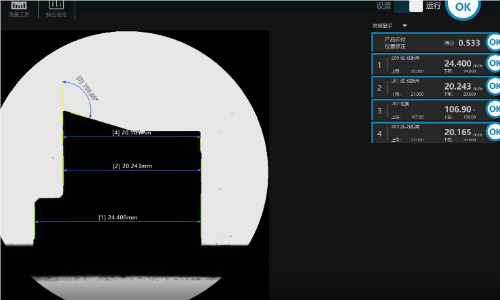

Projection measuring lens pursues the ultimate imaging quality, its imaging resolution is extremely high, and it can clearly present the details of tiny objects. In industrial measurement, it can be measured object contours, dimensions and other information accurately projected on the screen, the measurement accuracy can reach micron level or even higher. At the same time, the projection measurement lens on the image of the distortion control is very strict, to ensure the linearity and accuracy of the projected image, so that the measurement results are not affected by image distortion.

( B ) Ordinary projection lens

Although ordinary projection lenses can also provide clear images, the imaging resolution and accuracy are relatively low. In scenes such as home theater or conference rooms, it mainly meets the basic needs of people watching videos and displaying documents, and does not require high precision in the presentation of image details and size. Ordinary projection lenses will have image distortion to a certain extent, but this distortion will have less impact on the visual effect in daily viewing scenarios and will not affect its normal use.

Application Scenarios

( A ) Projection measurement lenses

Projection measuring lenses are mainly used in industrial manufacturing, precision testing, scientific research and other fields. In the machining industry, it is used to measure the size and shape error of parts; in electronic manufacturing, it can detect the size and positional accuracy of electronic components on circuit boards; in scientific research experiments, it is used to measure and analyze the size of microscopic objects. For example, in the manufacturing process of aerospace parts, the projection measuring lens is utilized to accurately measure complex shaped parts to ensure that the quality and performance of the parts meet strict standards.

( B ) Ordinary Projection Lens

Ordinary projection lens is widely used in family entertainment, business office, education and teaching scenes. In the family, it is used to build a home theater, so that users can enjoy an immersive viewing experience; in business meetings, it is used to display PPT, video and other information to assist the meeting discussion; in the school classroom, it is used for teaching demonstrations, so that the teaching content is more vivid and intuitive. For example, in the company's product promotion meeting, the use of ordinary projection lens will be product promotional video projected on the big screen, to attract customer attention.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com