Measurement of cylinder dimensions in real time --- POMEAS In-Line Measuring Instruments

In industrial production, cylindrical parts are widely used in machinery manufacturing, automotive parts processing, aerospace and many other fields. Accurate and real-time measurement of cylindrical dimensions plays a key role in guaranteeing product quality and improving production efficiency. With advanced technology and excellent performance, POMEAS in-line measuring instruments have become a powerful assistant in solving cylindrical dimension measurement problems.

Measurement Principle Analysis

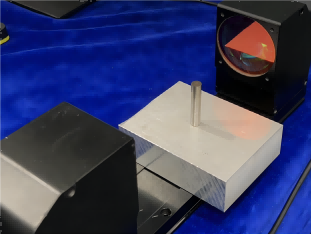

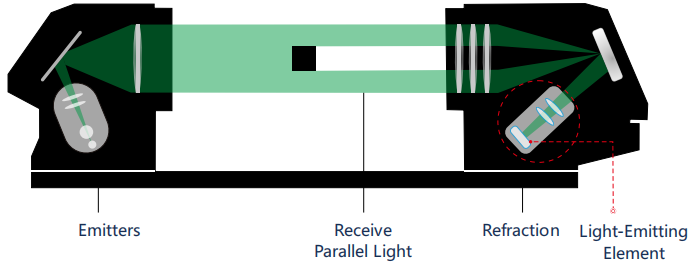

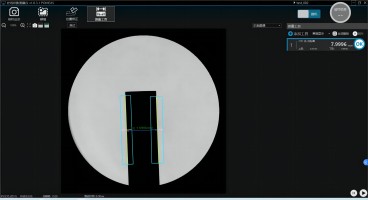

POMEAS online measuring instrument adopts advanced optical measurement principle, combined with high precision image acquisition and processing technology. It utilizes a laser or vision sensor to emit specific light, which is reflected when it hits the surface of the cylinder, and the sensor receives the reflected light and converts it into an electrical signal.

Through the accurate analysis of the reflected light angle, position and other information, combined with trigonometric functions and other geometric algorithms, the measuring instrument is able to quickly calculate the diameter, height, cylindricity and other key dimensional parameters of the cylinder. This non-contact measurement not only avoids the damage caused to the surface of the cylinder by traditional contact measurement, but also realizes high-speed, dynamic real-time measurement.

Measurement Advantages

( A ) High Accuracy Measurement

POMEAS in-line measuring instruments have extremely high measurement accuracy, accurate to the micron level. In the production of automobile engine block, the cylinder bore and other cylinder dimensions require high precision, POMEAS measuring instrument can accurately measure to ensure that each cylinder size meets the strict tolerance standards, to protect the performance and reliability of the engine.

( B ) Rapid Measurement

In modern production lines, the pace of production continues to accelerate, putting forward higher requirements for measurement speed. POMEAS online measuring instrument can complete a measurement in a very short time, and can provide real-time feedback of the measurement data to meet the needs of high-speed operation of the production line. For example, in the bearing production line, the measuring instrument can quickly measure the size of the inner and outer rings of the bearings, so that the production efficiency is greatly improved.

(C) Strong Stability

The measuring instrument has a stable hardware structure and optimized algorithms, in the complex industrial environment, such as high temperature, high humidity, strong electromagnetic interference and other conditions, can still maintain reliable measurement performance. In the size measurement of cylindrical steel billets in steel production enterprises, even in the harsh environment of high temperature and dust, POMEAS can work stably and provide accurate measurement data.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com