Electronics Manufacturing

-

PCB Inspection: It is used to detect whether the lines on the printed circuit board (PCB) have broken circuits, short circuits, poor etching, defective pads and other problems. The line scanning lens can scan along the line direction of the PCB, quickly obtain high-resolution images to help inspectors find subtle defects in time to ensure the quality of the PCB.

-

Semiconductor wafer inspection: In the semiconductor manufacturing process, the surface defects, scratches, particle contamination, etc. of wafers are inspected. Line scanning lens can scan the wafer surface line by line with high speed and high resolution, accurately identifying a variety of tiny defects, ensuring the production quality of wafers and improving the yield of semiconductor devices.

-

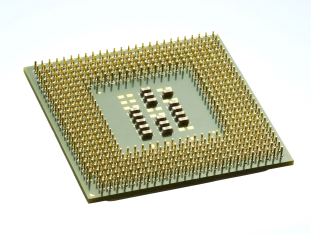

Electronic component inspection: for resistors, capacitors, inductors and other electronic components, such as the appearance of the size measurement, pin deformation detection, surface defect detection. Through the line scanning lens to obtain a clear image of the components, the use of vision algorithms to accurately analyze the shape, size, location, etc. of the components, to achieve rapid screening and quality control of electronic components.

Automobile manufacturing industry

-

Body Welding Inspection: In the automobile body welding production line, it is used to inspect the quality of the weld seam, such as whether the weld seam is full or not, whether there is leakage of weld, false weld, weld through and other defects. The line scanning lens can scan along the trajectory of the weld seam, obtain the image information of the weld seam in real time, and discover the welding defects in time by comparing with the standard image or adopting the specialized welding inspection algorithm, so as to ensure the strength and safety of the body structure.

-

Dimensional measurement of parts: High-precision measurement of the dimensions of automobile engine blocks, crankshafts, pistons and other parts. Line scanning lens combined with laser displacement sensors and other equipment, can quickly and accurately obtain the contour data of the parts, to achieve the key dimensions of the parts of the online measurement and quality control, to ensure the assembly accuracy and performance of the parts.

-

Auto Glass Inspection: It is used to inspect the surface flatness, scratches, bubbles, cracks and other defects of auto glass. The line scanning lens scans the glass surface at a high speed to obtain high-definition images, and then evaluates the appearance quality of the glass through image processing algorithms to ensure the optical performance and safety of automotive glass.

Printing and Packaging Industry

-

Print quality inspection: Inspection of the text, pattern, color, etc. of the printed matter, checking whether there is overprinting inaccuracy, lack of printing, leakage, uneven ink color, stains and other defects. The line scanning lens can scan along the transmission direction of the printed material, quickly obtain the image of the entire printed material, through comparison with the standard sample or the use of specific printing inspection algorithms, timely detection of printing quality problems, improve the quality of printed materials and production efficiency.

-

Packaging material inspection: Inspection of appearance defects and dimensional accuracy of packaging materials such as packaging cartons, plastic films and labels. For example, to detect whether the indentation of carton is clear and well molded, whether the thickness of plastic film is uniform, whether there are holes, scratches and other defects, whether the printed content of the label is complete and whether it is firmly affixed, and so on. The line scanning lens can quickly detect the quality problems of packaging materials to ensure the integrity of packaging and the appearance of the product image.

Textile industry

-

Fabric Defect Detection: It is used to detect yarn defects, holes, oil stains, color difference and other defects of fabrics in the production process. Line scanning lens scanning along the running direction of the fabric, real-time access to the fabric image information, through image processing technology to analyze the image, can quickly and accurately identify a variety of fabric defects, to improve the quality of the fabric inspection efficiency, reduce the error of manual testing and labor intensity.

-

Fabric texture detection: The texture structure of fabric is detected and analyzed to determine whether the fabric is tightly woven, whether the texture is uniform, and whether there are problems such as wrong weaving and omission of weaving. The high-resolution image acquired by the line scanning lens can clearly display the texture characteristics of the fabric, and the texture is analyzed and evaluated by using the vision algorithm to provide a basis for the quality control of the fabric and the adjustment of the production process.

Metalworking industry

-

Steel Surface Inspection: Inspection of cracks, scratches, oxidized skin, rust and other defects on the steel surface. Line scanning lens can be in the steel production line on the surface of the steel for rapid scanning, access to high-definition surface images, through image processing and analysis technology, can be timely found on the surface of the steel of a variety of defects, for the quality control of steel and subsequent processing to provide protection.

-

Surface quality inspection of metal parts: Roughness measurement and surface defect detection on the surface of machined metal parts. Line scanning lens combined with the optical measurement principle, can accurately measure the roughness parameters of the surface of metal parts, and detect the surface of the tiny cracks, sand holes, knife marks and other defects, to ensure that the surface quality of metal parts and the use of performance.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com