In industrial automation, machine vision, quality inspection and other fields, industrial camera as the core data acquisition equipment, its selection directly affects the performance and efficiency of the system. However, in the face of the wide variety of industrial cameras on the market, how to quickly and accurately select the right model? This article will start from the pixels, sensors, colors and other core parameters, detailed description of how to design an efficient industrial camera selection tool to solve the selection problem.

Confirming Core Requirements

Pixel is the first parameter of industrial camera selection, which directly determines the clarity and detail reproduction ability of the image. Selection tools need to intelligently recommend the appropriate resolution range based on the user's application scenarios.

Application scenarios are categorized:

① High-precision inspection (e.g. PCB defect detection): recommended 5 megapixels or more.

② dynamic capture (such as assembly line sorting): prioritize the frame rate and reduce the pixel requirement appropriately.

Resolution and field of view matching

① The tool needs to support the user to input the detection field of view (FOV) and accuracy requirements, and automatically calculate the required sensor size and resolution combination, to avoid the waste of pixels due to too large a field of view.

Sensor type

1、CCD sensor: high dynamic range, low noise, suitable for low light environment (such as semiconductor detection).

2、CMOS sensor: high frame rate, low power consumption, cost-effective, suitable for high-speed motion scenes (such as packaging line).

Sensor size and sensitivity

Tools need to be labeled sensor size (e.g., 1/1.8 inches, 2/3 inches) in relation to pixel size, large-size sensors perform better in low illumination. Provide sensitivity parameters (e.g. quantum efficiency, signal-to-noise ratio) for users to filter.

Color processing

1、Black and white camera: high resolution, high frame rate, suitable for measuring size, contour detection (such as metal parts defect identification).

2、Color camera: need to identify the color characteristics when used (such as food sorting, print detection).

3、Color depth and accuracy: tools need to support the color depth (such as 8bit, 12bit) filter, high-bit suitable for applications requiring high dynamic range (such as medical imaging). Provide Bayer filter type (RGGB, RGBW) options to optimize the color reproduction effect.

Function Module

1、Parameter input and filtering users to enter the core requirements (field of view, accuracy, frame rate, lighting conditions, etc.), the tool automatically filter mismatched camera models. Provide parameter priority settings (such as “resolution priority” or “frame rate priority”).

2、Intelligent recommendation algorithm generates a recommendation list based on the parameter weights input by the user (e.g. 60% resolution, 30% frame rate, 10% cost). Combined with the industry case library, it recommends commonly used models in similar scenarios.

3、Parameter comparison and visualization generates a comparison table of the parameters of multiple cameras, highlighting key differences (such as pixel size, maximum frame rate). Provide imaging effect simulation diagrams, visually display the effect of different resolution/color mode differences.

4、Interface Matching: Support filtering camera interface types (GigE, USB3.0, CoaXPress).

5、Environmental adaptability: Filter according to temperature, protection level (IP67) and other conditions.

Example

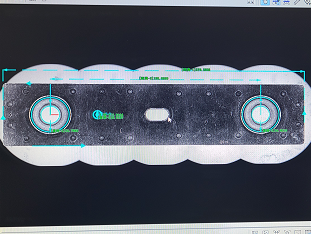

Take lithium battery appearance inspection as an example:

-

User input: field of view 100mm x 100mm, detection accuracy 0.05mm, general lighting conditions, budget within 50,000 RMB.

-

Tool Recommendation:

-

Resolution: 5 megapixels (meets 0.05mm accuracy).

-

Sensor: CMOS (high frame rate adapted to production line speed).

-

Color Mode: Black & White (No need for color to detect scratches and bumps).

-

Interface: GigE (stable transmission over long distances).

-

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com