Image Measuring Instrument for Smartwatch Band Hole Concentricity Inspection

In the manufacturing process of smartwatches, the concentricity of the band's round holes is the core element of product quality and user experience. Once there is any deviation in the concentricity of the band's round holes, it will not only greatly reduce the assembly precision of the band and the watch body, but will also most likely lead to the discomfort of the user when wearing the watch, and even negatively affect the overall aesthetics of the smartwatch. Therefore, the accurate detection of the concentricity of the round holes of smartwatch bands has become an indispensable and important part of the production process. With its unique advantages, image measuring instrument plays a key role in this inspection field.

Principle of operation of the image measuring instrument

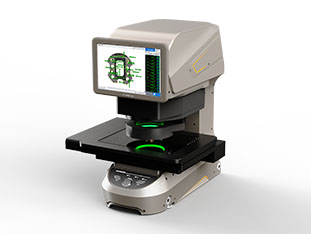

The Image Measuring Instrument incorporates a number of advanced technologies such as optical imaging, digital image processing and precision mechanical motion control. It images the round holes of the smartwatch band through a high-resolution optical lens, converting the physical image of the holes into a digital image signal. Subsequently, the professional image processing software built into the system will analyze the acquired image and accurately identify the contour of the round hole using algorithms such as edge detection and feature extraction. Based on the contour information, the software can accurately calculate the coordinates of the center of each round hole, and then derive the concentricity value between each round hole through a specific algorithm.

Image Gauge Inspection Advantages

1、High-precision measurement: The image measuring instrument adopts advanced optical system and image processing algorithm, which can realize sub-micron level measurement accuracy. Compared with the traditional contact measurement method, it avoids the measurement error caused by the contact between the probe and the measured object, which is especially suitable for the concentricity detection of the round holes of smartwatch watch bands that require very high precision. For example, in the production of high-end smartwatches, the fine dimensional tolerances require that the image measuring instrument can accurately detect very small concentricity deviations to ensure that product quality reaches the top standard.

2、Non-contact detection: This detection method will not cause any damage to the surface of the watchband, which is especially suitable for detecting those watchbands whose surface materials are more sensitive or easy to be scratched. Whether the strap is made of leather, silicone or metal, the image measuring instrument can complete accurate detection without contact, effectively protecting the integrity of the product.

3、Rapid detection: The image measuring instrument has fast image acquisition and processing capabilities, and is able to complete the concentricity detection of multiple watch band holes in a short period of time. In the large-scale production line of smart watches, this feature greatly improves the inspection efficiency, meets the requirements of the production line for inspection speed, and effectively shortens the production cycle of the product.

Operational Processes

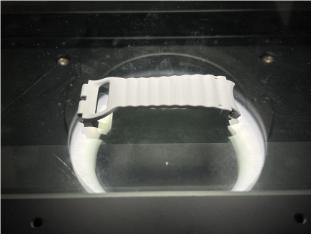

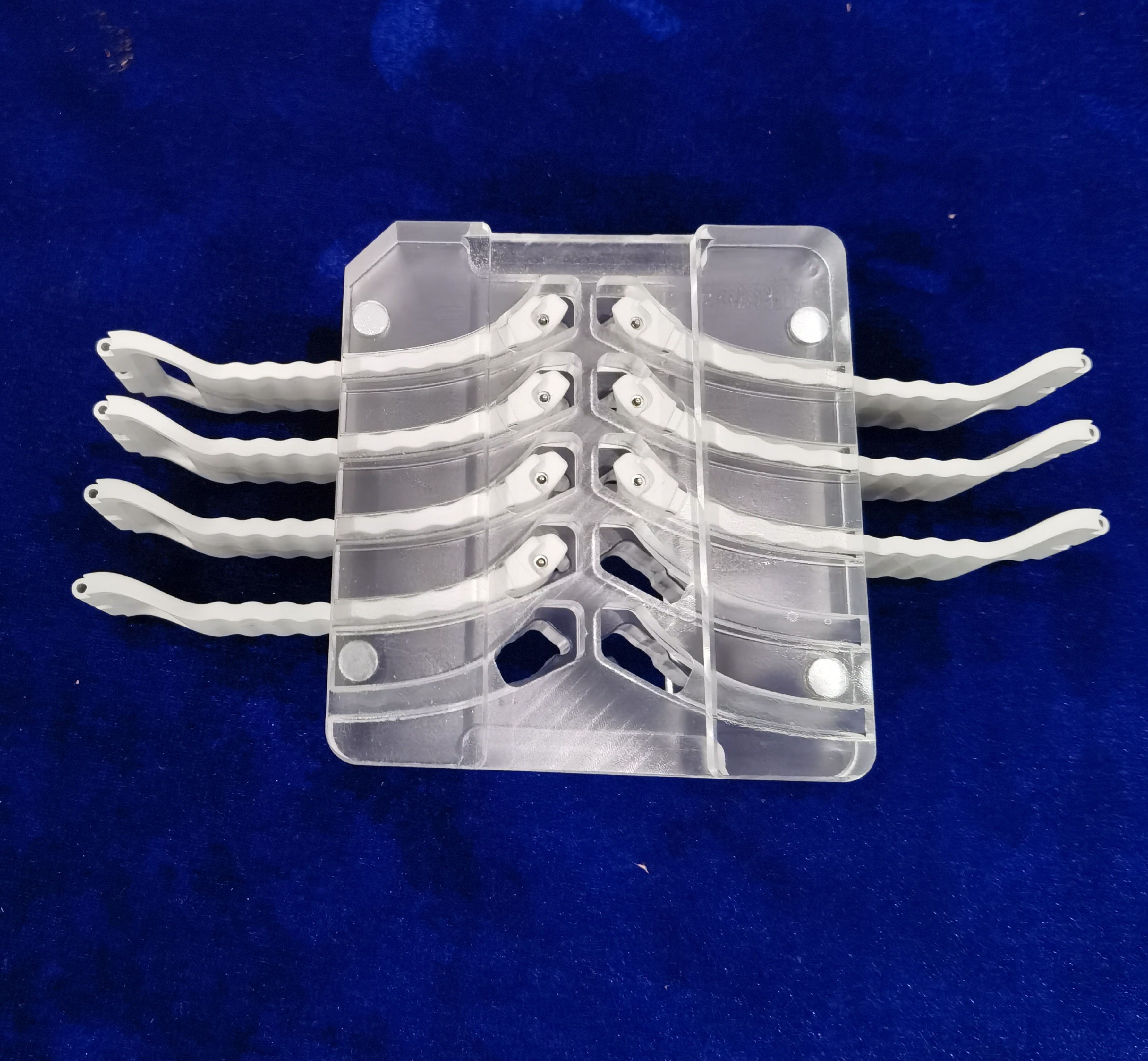

1、Sample Preparation: Place the smartwatch band to be tested on the working table of the image measuring instrument, make sure that the position of the band is fixed and the round holes are within the measurement field of view. In order to ensure the accuracy of the measurement, it may be necessary to use a special fixture to locate and fix the strap.

2、Parameter setting: According to the size and accuracy requirements of the round hole of the strap, set the corresponding measurement parameters on the operation interface of the image measuring instrument, such as image acquisition resolution, measurement accuracy, measurement range and so on. Reasonable setting of these parameters is crucial for obtaining accurate measurement results.

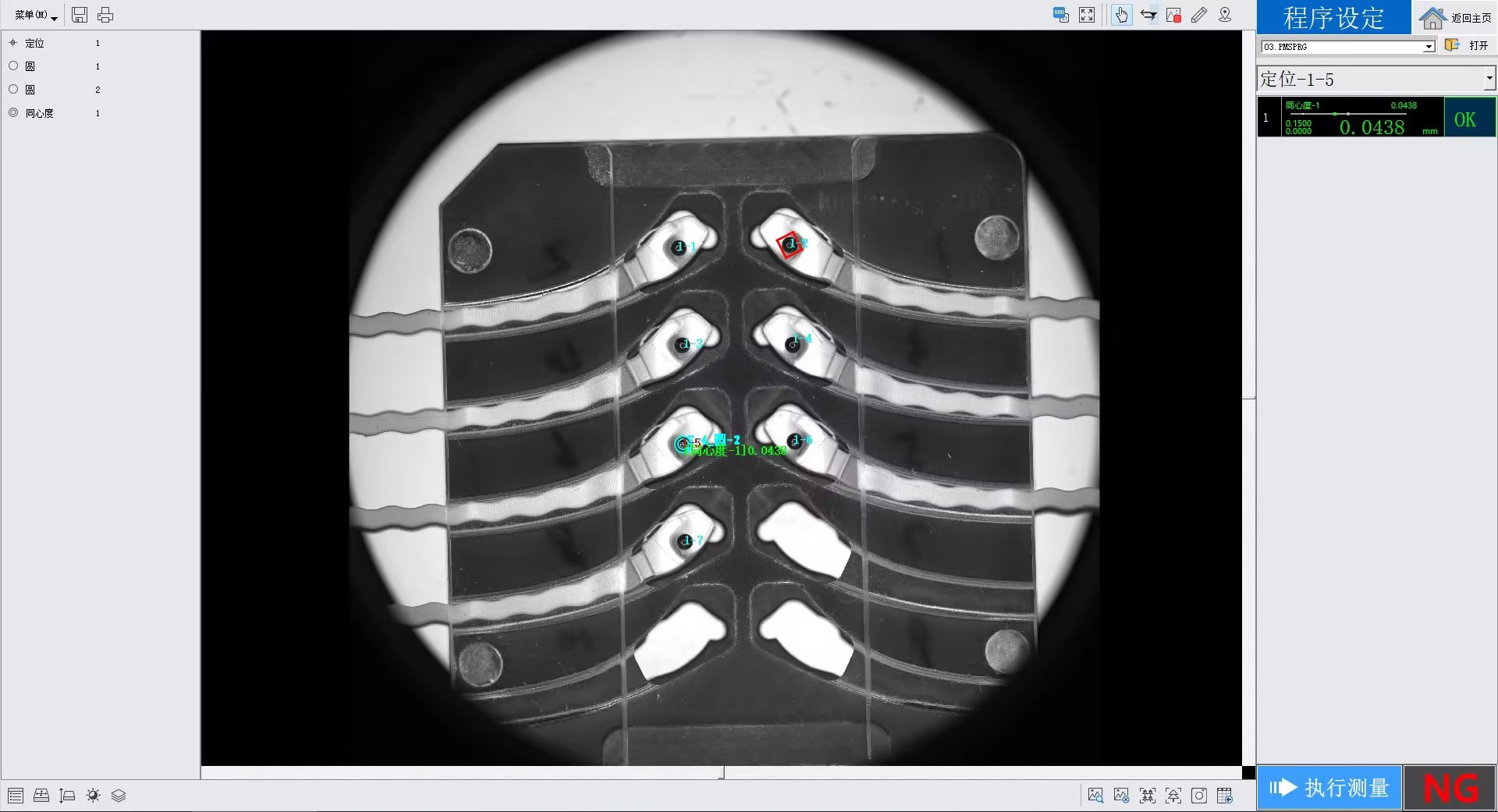

3、Image acquisition and analysis: Start the image measuring instrument, the system automatically acquires images of the round holes of the strap. After the acquisition is completed, the image processing software immediately analyzes and processes the image, identifies the contour and center position of the round hole, and calculates the concentricity value. The whole process does not require too much manual intervention, realizing automatic detection.

4、Results output and judgment: Measurement results will be displayed in an intuitive form on the operation interface, including the concentricity value of each round hole, whether it meets the preset tolerance range and other information. The operator can quickly judge whether the quality of the strap is qualified or not according to these results, and mark the unqualified products for subsequent processing.

Using POMEAS image measuring instrument to inspect the concentricity of the round holes of smart watch bands is an efficient and accurate inspection method. It can ensure the manufacturing quality of smart watch bands and improve the wearing comfort and aesthetics of the products.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com