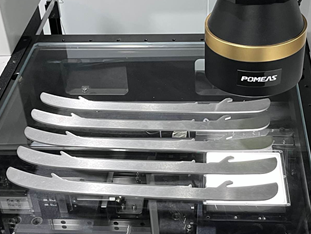

Dual telecentric lenses enable batch measurement of ice skate dimensions

In the field of ice sports equipment manufacturing, the dimensional accuracy of ice skates plays a key role in the performance of athletes. The right size of ice skates can ensure that the athletes can skate stably, steer flexibly, and deliver power efficiently on the ice surface. With the expansion of ice skate production scale, how to realize fast and accurate batch size measurement has become the focus of the industry. The double telecentric lens, with its excellent optical performance, provides an innovative solution for batch measurement of ice skate size.

The unique feature of the double telecentric lens is that it has an object-side telecentric optical path and an image-side telecentric optical path. This special design enables the lens to effectively eliminate measurement errors caused by changes in object distance during the measurement process. In the ice skate batch measurement scenario, there may be slight differences in the placement of different ice skates, and ordinary lenses are easily affected by this, resulting in measurement deviation, but the double telecentric lens is able to stably acquire high-precision images, no matter how the position of the ice skate on the measuring table changes, it can accurately capture its contour, which will provide a reliable basis for the subsequent dimensional calculations.

The traditional manual measurement method requires operators to measure each dimension of the ice skates one by one using gauges, which is not only time-consuming and laborious, but also prone to human errors.

The dual telecentric lenses with the automated measurement system can quickly scan the ice skates and complete the size measurement of a large number of ice skates in a short period of time. Through image acquisition and professional image analysis software, the system can automatically identify the key dimensional features of the ice skates, such as length, width, curvature, etc., and quickly calculate the accurate values, greatly reducing the measurement cycle and meeting the needs of mass production.

The use of dual telecentric lenses is also of great importance when it comes to quality control. Precise dimensional measurements can ensure that each ice skate meets strict quality standards. Once the size of the ice skates is found to be out of tolerance during the production process, the manufacturer can adjust the production process in time to avoid substandard products from entering the market. This not only helps to improve product quality, but also strengthens brand reputation and provides athletes with more reliable equipment protection.

The double telecentric lens realizes fast and accurate batch size measurement of speed skating ice skates with the advantages of high precision and high efficiency measurement.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com