In the field of automobile manufacturing, the quality of automobile wheels is related to the safety, maneuverability and aesthetics of vehicles. The automotive wheel contour scanning measurement technology is becoming the key link to ensure the quality of the wheel hub, like a precision eye, to escort the automobile production.

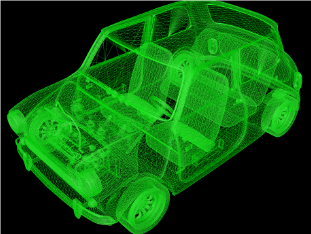

Automotive wheel contour scanning measurement is a method to accurately measure the profile of a wheel using advanced measurement techniques. Its principle is mainly based on optical measurement, laser measurement and other technologies. Taking laser measurement as an example, by emitting a laser beam to the surface of the wheel hub, the laser beam is reflected and then received by the sensor, and according to the time difference between the emission and reception of the laser or the angle change, the three-dimensional coordinates of each point on the surface of the wheel hub are calculated, so as to construct a precise contour model of the wheel hub.

This technology is widely used in automobile production. In the wheel production line, it can monitor the manufacturing process of the wheel in real time, and once it is found that there is a deviation between the wheel contour and the design standard, the production parameters can be adjusted in time to avoid producing a large number of unqualified products, and effectively improve the production efficiency and product quality. In the wheel quality inspection link, it can accurately detect whether there are deformation, size deviation and other problems in the wheel hub to ensure that every wheel hub entering the market meets the strict quality standards.

Compared with traditional measurement methods, automotive wheel hub profile scanning measurement technology has significant advantages. First of all, it has a very high measurement accuracy, can be accurate to the micron level, which is difficult to reach the traditional gauge. Secondly, the measurement speed is fast, and the measurement of the entire wheel hub profile can be completed in a short period of time, which greatly improves the inspection efficiency. In addition, the technology can realize non-contact measurement, avoiding damage to the wheel surface and ensuring the integrity of the wheel.

Automotive wheel hub contour scanning measurement technology plays an indispensable role in automobile manufacturing. With the continuous progress of science and technology, this technology will also continue to develop, and the measurement accuracy and efficiency will be further improved to provide stronger support for the high-quality development of the automotive industry.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION