In recent years, with the rapid development of machine vision technology, 3D industrial cameras have been more and more widely used in the field of industrial inspection. Its efficient, flexible and non-contact measurement characteristics make it a strong competitor of traditional contact measurement methods. However, in the face of more professional three-dimensional profile measurement equipment, whether 3D industrial cameras can be completely replaced, is still a question worthy of in-depth discussion.

Advantages of 3D industrial cameras:

1. Efficient and fast: 3D industrial camera can acquire a large amount of three-dimensional data in a short period of time, realizing fast measurement and significantly improving production efficiency.

2. Non-contact measurement: no need to contact the object to be measured, avoiding the risk of damage to precision workpieces, especially suitable for soft, deformable or high temperature object measurement.

3. High flexibility: 3D industrial cameras can be flexibly adjusted to the measurement range and accuracy according to different measurement needs, and are easy to integrate into automated production lines.

4. Relatively low cost: Compared with professional 3D contouring equipment, 3D industrial cameras are cheaper and easier to be accepted by small and medium-sized enterprises (SMEs).

Advantages of 3D contour measurement equipment:

1. High measurement accuracy: Professional 3D contour measurement equipment usually adopts high-precision sensors and complex algorithms, which can realize micron or even nanometer-level measurement accuracy to meet the demand for high-precision measurement.

2. Wide measurement range: According to different measurement requirements, different specifications of the measurement equipment can be selected to realize the accurate measurement from micro to macro.

3. More powerful functions: In addition to basic dimensional measurement, 3D contour measurement equipment can also be used for morphology analysis, roughness measurement, defect detection and other more complex measurement tasks.

Can 3D industrial cameras replace 3D contouring equipment?

3D industrial cameras and 3D profiling equipment each have their own advantages and are suitable for different application scenarios.

-

For scenarios where accuracy is not required and fast measurements are needed, For example, part size inspection, appearance defect inspection, etc., 3D industrial camera can replace the traditional contact measurement method and become a better choice with its efficiency and flexibility.

-

For scenarios that require high precision and complex measurements, For example, for topographic analysis of precision parts, surface roughness measurement, etc., professional 3D contour measuring equipment is still irreplaceable.

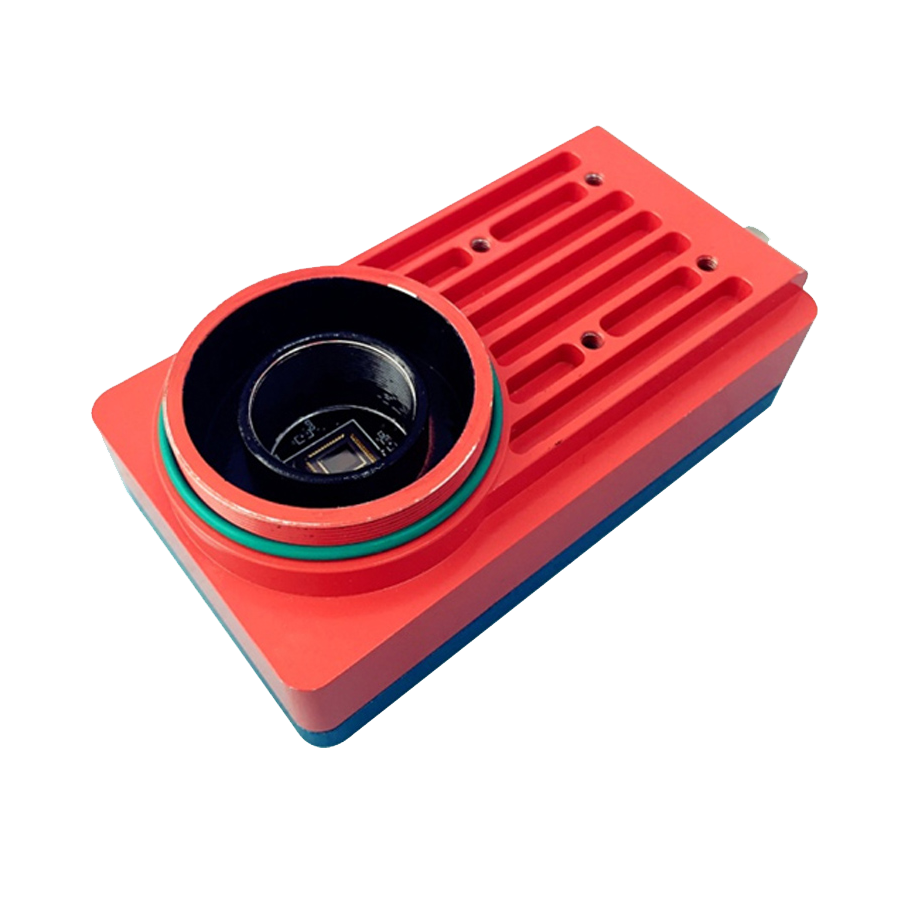

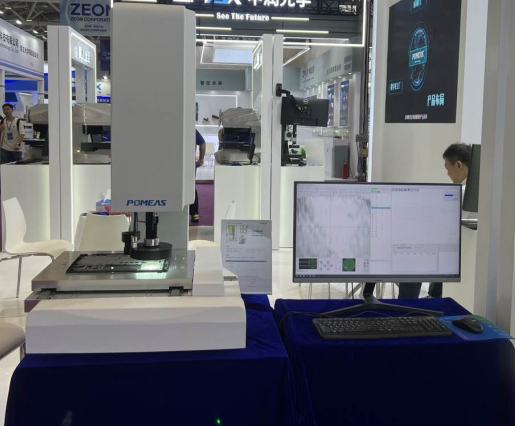

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com