In the field of precision manufacturing and quality control, the importance of measuring equipment cannot be overstated. Whether it is product development, manufacturing, or quality inspection, high precision measuring tools are indispensable. However, there is a wide range of measuring equipment on the market, from basic image measuring instruments and image measuring instruments to advanced 3D contour measuring instruments, high-precision dimensional measuring instruments, and even three-dimensional image measuring instruments, each of which has its own unique application scenarios and technical advantages. Faced with so many choices, how to select a suitable measuring equipment has become a difficult problem for many enterprises and technicians.

Define measurement requirements

Defining your measurement needs is the first step in purchasing measurement equipment. You need to know exactly what needs to be measured, is it 2D dimensions or 3D contours? How high is the accuracy requirement of the measurement? Is the measurement environment complex and variable? The answers to these questions will directly affect the type and configuration of the equipment you buy.

Understanding Equipment Types

-

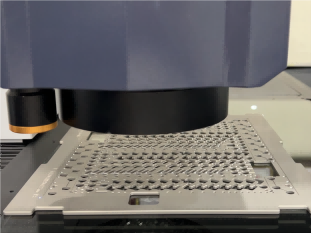

2D Measuring Devices: For applications where only 2D dimensions need to be measured, image measuring machines and image measuring devices are a good choice. They magnify and project the object to be measured onto a screen through the optical imaging principle, and automatically recognize and calculate the dimensions through software. These devices are easy to operate and fast to measure, making them ideal for quick inspections on large-scale production lines.

-

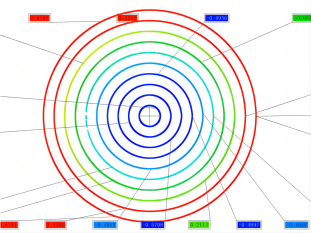

3D Measuring Equipment: If you need to measure three-dimensional contours or high-precision dimensions, 3D contour measuring instruments, high-precision dimensional measuring instruments, and three-dimensional image measuring instruments are more suitable. They use advanced technologies such as lasers, white light interference, structured light, etc. to accurately capture the three-dimensional shape of the object to be measured and provide comprehensive size and shape information.

Consider equipment performance

After determining the type of equipment, the next step is to focus on the performance parameters of the equipment. This includes, but is not limited to, measurement accuracy, measurement range, repeatability, resolution, ease of operation and so on. Especially for high-precision requirements of the occasion, the accuracy and repeatability of the equipment is particularly important. At the same time, ease of operation is also a factor that can not be ignored, an easy to use, easy to operate equipment can greatly improve work efficiency.

Assessing service capacity

After-sales service is equally important when choosing measurement equipment. A quality after-sales service team can respond to customer needs in a timely manner to provide technical support and maintenance services. When choosing equipment, you may want to learn more about the after-sales service policy of several suppliers, and choose those who can provide a full range of high-efficiency after-sales service partners.

Field trips and trials

Before making a final decision, it is wise to visit the supplier's manufacturing environment and equipment demonstration center to try out the equipment yourself. By operating and observing the equipment in the field, you can visualize its performance and ease of operation, thus making a more informed purchasing decision.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com