What makes telecentric lenses dominate the field of high-precision measurement?

From the manufacture of precision electronic components to the inspection of aerospace parts, telecentric lenses have become the “standard” for many high-precision measuring devices due to their excellent performance. So, what exactly makes telecentric lenses dominant in this field?

Unique Optical Design Lays the Foundation for Accuracy

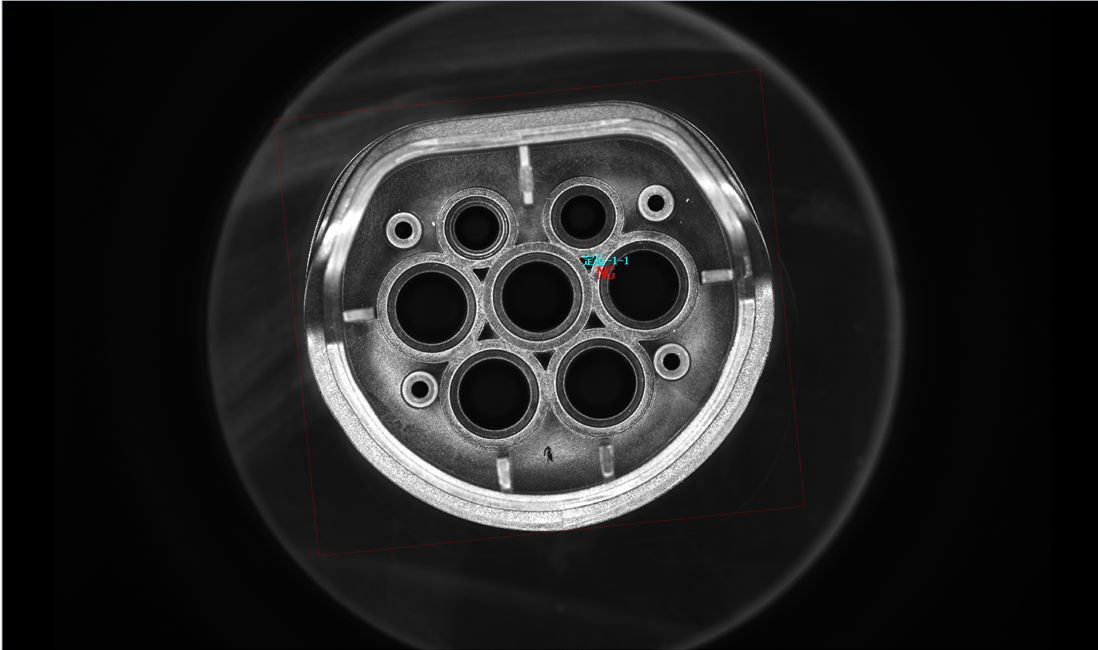

The unique optical design of telecentric lenses is a central factor in their ability to achieve high-precision measurements. Unlike ordinary lenses, telecentric lenses use a special optical path structure that allows the main light rays to propagate parallel to the optical axis. This design brings many advantages, the most notable of which is the elimination of parallax. In conventional lenses, changes in the object distance can lead to changes in imaging size and position, resulting in measurement errors. In contrast, telecentric lenses, through the design of parallel main light rays, the size and position of the imaging remains almost constant regardless of the position of the object within the measurement range, which provides a solid foundation for high-precision measurements.

For example, in the manufacturing process of cell phone chips, the width and spacing of circuit lines on the chip are often at the micron or even nanometer level. Measurement with a telecentric lens captures precise information about the size and position of these tiny structures, and even slight displacements of the chip on the measuring table do not affect the accuracy of the measurement results.

Extremely low distortion for measurement accuracy

Another key feature that makes telecentric lenses dominate the field of high-precision measurement is their extremely small distortion. In high-precision measurements, even the slightest image distortion can lead to large deviations in the measurement results. Telecentric lenses control image aberrations to a very low level by optimizing the material and curvature of the optics, as well as the precision manufacturing process. Generally speaking, the distortion rate of telecentric lenses can be controlled within 0.1% or even lower.

For example, the dimensional accuracy of engine block, crankshaft and other key components in the precision measurement of automobile parts directly affects the performance and reliability of the automobile. The use of telecentric lenses for the measurement of these parts can ensure the accuracy of the measurement results, timely detection of dimensional deviations, to avoid quality problems caused by unqualified parts.

High resolution provides sharp details

In high-precision measurements, clear image details are essential. Telecentric lenses are characterized by their high resolution, which enables them to capture minute features on the surface of an object. This allows telecentric lenses to provide a wealth of detailed information for more accurate measurements when measuring tiny objects or fine structures.

For example, in the jewelry appraisal industry, the cut surface and texture of gemstones need to be accurately measured and evaluated. The high resolution of the telecentric lens can clearly present every detail of the gemstone, helping the appraiser to accurately determine the quality and value of the gemstone.

Wide range of application scenarios to verify strength

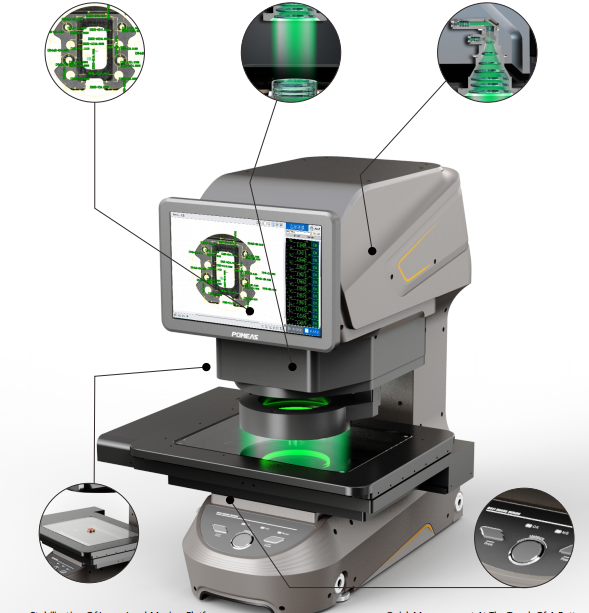

The excellent performance of telecentric lenses has been widely used and verified in many fields. In the electronics manufacturing industry, it is used to detect whether the electronic components on the circuit board are well soldered and whether there are defects on the chip pins, etc. In the machinery manufacturing industry, it is used to measure the dimensional accuracy and shape error of mechanical parts, etc. In the medical field, it is used for high-precision measurements and analyses of biological samples and medical devices.

With its unique optical design to eliminate parallax, minimal aberration, high resolution, and wide range of applications in electronic, mechanical, and medical fields, telecentric lenses have become the first choice for high-precision measurements, and with the development of science and technology and the increase in precision requirements, their role will become more and more important, and POMEAS can provide customers with the relevant solutions.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com